Introduction

Rooftop solar has seen huge adoption across India in recent years. Costs of solar panels have come down, government support has grown, and more families are choosing clean energy. In most Indian homes, the roof is made of RCC, so this surface naturally becomes the preferred place for installing solar panels.

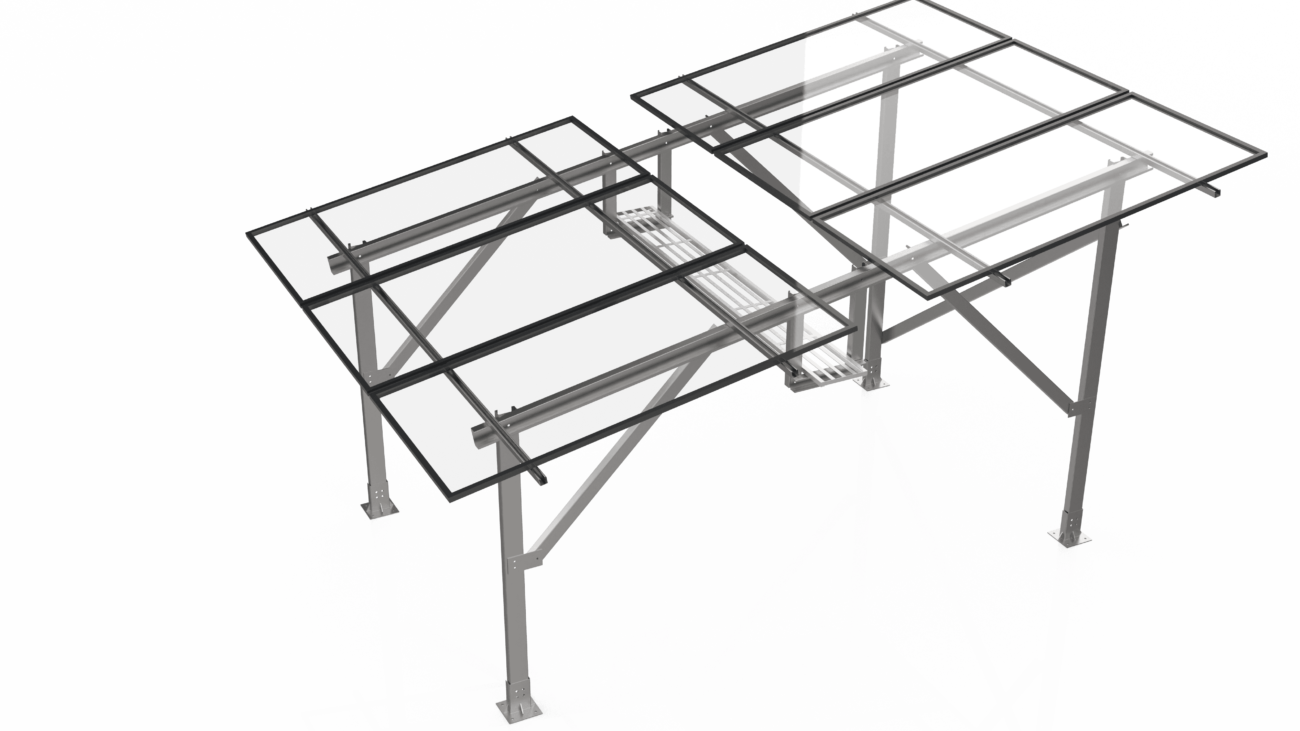

A mounting structure plays a very important role in any rooftop solar project. It holds the panels in position, maintains the correct angle for sunlight, and keeps the system stable for more than 20 years. For a long time, most residential systems were made using on-site fabrication. But things are changing. Pre-fabricated RCC rooftop solar structures are becoming the preferred choice because they are faster, cleaner, more reliable and easier to install.

This guide explains everything you need to know about prefab RCC rooftop solar structures. The intention is to educate both EPC companies and homeowners in simple and clear language, without sounding promotional.

1. What Is a Rooftop Solar Mounting Structure?

A rooftop mounting structure is the frame that supports the solar panels. Its main functions are:

- Holding the panels at the correct angle

- Keeping them stable during strong winds and heavy rainfall

- Maintaining long-term strength and safety

- Allowing access for cleaning and service

Common types of rooftop mounting structures

- RCC rooftop structures

- Sheet metal roof structures

- Tilted frames

- Custom architectural structures

RCC rooftops are extremely common in India, which makes RCC solar mounting structures the most widely used solution for homes.

2. Why Site Fabrication Became the Norm in India

For many years, installers preferred fabricating structures directly at the site. This happened because every home was different, and local fabrication seemed like the easiest way to adjust to different roof layouts.

However, the site fabrication approach has several drawbacks

- Heavy dependence on skilled fabricators

- Variations in quality from one project to another

- Mistakes in cutting, welding or alignment

- Longer timelines due to multiple stages of work

- Aesthetic issues like uneven welds or patchy painting

- Extra hidden costs from rework, wastage and delays

As the industry matured, both EPCs and homeowners started looking for safer and more professional ways to build rooftop structures. This is where prefab structures stepped in.

3. What Are Pre-Fabricated RCC Rooftop Solar Structures?

A pre-fabricated RCC rooftop solar structure is a mounting system that is designed and manufactured in a factory using standardised components. The structure is produced under controlled conditions, tested for strength and accuracy, and delivered to the project site in ready-to-assemble parts.

These systems usually consist of:

- Standardised brackets and frames

- Pre-cut members

- Bolt-based assembly

- Coating options like pre-galvanized, Galvalume, Magnelis, HDG or MS

- Variants with and without walkways

Prefab structures are engineered using modern software and simulation tools. Since they are made using defined processes, they offer predictable quality and better long-term stability.

4. Benefits for EPCs and Solar Installers

1. Very low installation time

The biggest advantage of prefab structures is speed. A structure that takes two to three days to fabricate on-site can be erected in less than one hour using a prefab system. This allows EPCs to complete more projects in the same time and improve their monthly output.

2. No dependency on fabricators

Finding good fabricators is one of the biggest challenges in the Indian solar market. Prefab structures remove this dependency. Any trained technician can assemble the structure with simple tools. This reduces labour unpredictability and lowers supervision requirements.

3. Better aesthetics and a more professional finish

Homeowners pay attention to how the solar system looks. Prefab systems offer neat and clean finishes with uniform angles. This improves customer satisfaction and increases the chance of getting referral projects.

4. Scientifically engineered and tested

Prefab structures are designed using simulations and tested for different loads. This gives EPCs confidence that the structure will withstand heavy rains, winds and temperature variations. Quality control is much better compared to on-site work.

5. Smooth customization and quick delivery

While prefab structures follow standard designs, they are still flexible. Many suppliers offer fast customization for height, tilt, roof conditions, coating and module layout. For example, Structura Metal provides standardised designs that cover almost 90 percent of residential needs and also gives quick custom solutions when required.

6. Ready coating options

EPCs often need different coatings depending on location. Prefab structures come with coating options ready from the start such as pre-galvanized, Galvalume, Magnelis, HDG or MS. This removes uncertainty and speeds up project planning.

5. Benefits for Homeowners and End Users

A residential solar system is expected to last more than 20 years. Homeowners naturally want a structure that is safe, reliable and visually appealing.

1. Long-term reliability

Fabricated structures depend heavily on the skill of the person at the site. Incomplete welds, weak joints or incorrect alignment can create fault lines. These issues become dangerous during storms, strong winds or long-term corrosion.

Prefab structures eliminate these risks. They are engineered, tested and produced under controlled conditions, which gives homeowners confidence in long-term stability.

2. Cleaner and better aesthetics

Prefab structures look much cleaner because there are no rough welds or mismatched angles. The finish is uniform and the system blends better with the roof.

3. Quick and comfortable installation

Since installation is very fast, homeowners experience minimum disturbance. There is no cutting, welding or scrap material on the roof. Everything is simple and clean.

4. Protection for the rooftop

Fabrication at site involves welding sparks, cutting tools and heavy equipment, which can damage the roof surface or create seepage points. Prefab avoids all such risks and keeps the roof safe.

6. Technical Considerations for RCC Prefab Structures

1. Understanding structural loads

A good prefab structure is designed for:

- Dead load of the panels and structure

- Live load

- Wind loads and uplift forces

- Seismic movement

- Thermal expansion

Manufacturers use engineering software and simulations to calculate these loads.

2. Choosing the right coating

Different climates in India require different coatings:

- Coastal locations: Magnelis or HDG

- High humidity: Galvalume or HDG

- Dry regions: Pre-galvanized or painted MS

- Industrial areas: Higher corrosion-resistant coatings

3. Bolted connections over welded ones

Bolted connections provide predictable strength, are easy to inspect and can be replaced in the future. Welded connections at site depend on the welder’s skill and are more prone to errors.

4. Installation checklist

A simple but effective checklist includes:

- Checking RCC roof condition

- Following the engineering drawing layout

- Tightening bolts using the right torque

- Ensuring correct alignment before mounting the panels

- Final inspection before handover

Structura Metal provides simulation reports, testing reports and material certificates that help EPCs validate all technical aspects before installation.

7. Myths and Misconceptions About Prefab Structures

Myth 1: Prefab means one size fits all

This is not true. Modern prefab structures come in many standard designs that cover almost all common residential requirements. In cases where the site needs something unique, customization is simple and quick. Structura Metal offers standardised designs for most projects and easy custom options for the remaining needs.

Myth 2: Prefab is more expensive

People often compare only the material price and ignore the overall cost of fabrication. When you consider scrap wastage, mistakes in cutting, extra vehicle trips, rework, roof damage, delays and labour issues, the cost of fabrication and prefab usually turns out to be similar.

But prefab actually helps EPCs earn more because:

- They complete more projects

- They get better customer reviews

- They receive more referrals

- They avoid costly rework

So in terms of overall economics, prefab is the smarter choice.

Myth 3: Prefab is less durable

Fabricated structures depend on how carefully a welder works. If the welder is in a hurry or makes a mistake, the joint becomes weak. Over time these joints become the first points to fail during harsh weather.

Prefab structures are engineered and simulation-tested. They are free from welding errors, which makes them stronger and more reliable in the long run.

8. How to Choose a Good Prefab Structure Supplier

1. Engineering and design transparency

Ask for:

- Engineering drawings

- Structural load calculations

- Simulation reports

- Material test reports

2. Verified material certificates

A good supplier will share coating certificates and material quality documents.

3. Installation support

Look for manuals, videos, phone support and guidance during installation.

4. Ability to customize

Check if the supplier can make height changes, tilt changes, walkway options or adjustments based on rooftop layout.

Subtle Note

Structura Metal provides engineering drawings, simulation results, testing reports and material certificates on request. This helps EPCs execute projects with clarity and confidence.

9. A Simple Real-World Scenario: The ROI of Prefab

Fabrication method

- Two to three days of fabrication work

- One more day for finishing and alignment

- Scrap removal

- Extra supervision

- Skilled labour requirement

Prefab method

- Installation completed in 45 to 60 minutes

- Neat finish with no rework

- Minimal labour

- No scrap

- Predictable quality

- Faster invoicing

When an EPC completes 15 to 20 projects a month, this efficiency makes a meaningful difference in business output.

10. Frequently Asked Questions

1. Is prefab suitable for all RCC rooftops?

Yes. Standard designs cover most cases and customization handles the rest.

2. Will prefab structures handle strong winds?

Yes. They are tested and designed to meet wind load requirements.

3. What coating should I choose?

Coastal areas need higher corrosion resistance. Inland regions can use more economical coatings.

4. Are prefab structures costlier?

Not when you evaluate the full project cost. In many cases they are more economical.

5. Do prefab structures look better?

Yes. The finish is more uniform and cleaner.

6. Can anyone assemble a prefab structure?

With basic training, yes.

7. Are prefab structures customizable?

Yes. Height, tilt, walkway and coating options can be adjusted.

8. Does prefab reduce roof damage?

Yes. There is no welding or heavy cutting on the roof.

9. What documents should a supplier provide?

Material certificates, test reports, engineering drawings and installation guidelines.

10. How fast can a prefab structure be delivered?

Usually within a few days, depending on coating and customization.

Conclusion

As India continues to adopt rooftop solar at a rapid pace, the industry needs mounting solutions that are fast, reliable and long lasting. Prefab RCC rooftop structures offer a major improvement over traditional fabrication because they provide consistent quality, faster installation, better aesthetics and superior long-term durability.

For EPCs, they help scale operations and deliver more professional installations.

For homeowners, they ensure safety and long-term value.

Structura Metal supports both standard and custom prefab solutions for Indian rooftops and provides all the technical documentation needed for confident execution.