I. Understanding Anodized Aluminum

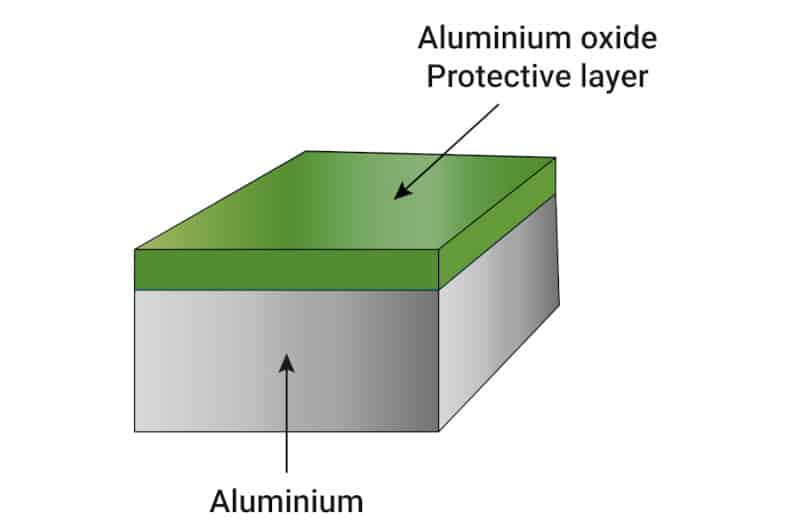

Anodized aluminum is an aluminum alloy that undergoes a process called anodization, in which an oxide layer forms on the surface of the metal.

Key properties of anodized aluminum include

- Corrosion resistance

- Strength

- Durability

- Light weight

The anodization process:

- Thickens the natural oxide layer on the aluminum surface

- Creates a transparent, hard and protective finish

The resulting surface resists:

- Corrosion

- Wear

- Weathering

- Scratching

Benefits of the anodized layer:

- Corrosion resistance

- Protects against oxidation, rust, staining

- Surface hardness

- More scratch and abrasion resistant

- Durability

- Withstands weathering and harsh conditions

- Aesthetic versatility

- Available in a range of finishes and colors

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminium. This coating is highly durable, resistant to weathering, and provides excellent insulation. Anodized coatings are often used on aluminium solar mounting structures. AA10 is the common industry standard of anodized coating which is 10 microns thick.

Common applications for anodized aluminum:

| Application | Benefits Provided |

| Building exteriors | Corrosion protection, strength |

| Electronics | Light weight, thermal performance |

| Solar panel frames | Corrosion resistance, strength-to-weight ratio |

The anodized aluminum layer can be thinner or thicker depending on the required characteristics:

- Hard-coat anodizing produces thicker oxide for wear resistance

- Architectural anodizing provides corrosion protection and aesthetic options

Anodization transforms aluminum into a tougher, more durable and weather-resistant material while retaining its light weight. This makes it well-suited to applications like solar panel frames that demand corrosion resistance, strength and durability in outdoor environments. The thermal conductive properties also aid solar panel thermal performance.

II. Advantages of Anodized Aluminum Frames

Anodized aluminum frames offer several key strengths that make them an exceptional choice for solar panel installations:

Corrosion Resistance

- The anodized surface strongly resists corrosion, oxidation, and rust

- Ideal for outdoor use in high humidity, coastal, industrial and other harsh environments

- Requires very little long-term maintenance

Strength-to-Weight Ratio

- Frames are lightweight yet highly durable

- High strength-to-weight ratio enables stable structures without added weight

- Easier transportation, handling and installation

- Suitable for elevated and pole-mounted solar arrays

Aesthetic Versatility

- Available in a diverse range of architectural finishes and colors

- Can mimic styles like wood grain or granite

- Blends into natural scenery or matches building exteriors

- More aesthetically appealing than industrial-looking steel frames

Thermal Performance

- Excellent heat dissipation properties

- Prevents solar panels from overheating

- Enhances efficiency and prolongs operational lifespans

- Ideal for solar installations in hot climates

Anodized aluminum frames combine optimal corrosion resistance, strength, durability and flexibility in design to meet the demanding structural and environmental needs of solar panel systems. The exceptional thermal performance also enhances efficiency. This blend of technical and aesthetic qualities makes anodized aluminum an outstanding solar panel frame material for varied installations.

III. Applications

Anodized aluminum frames are extensively used in diverse solar panel installations:

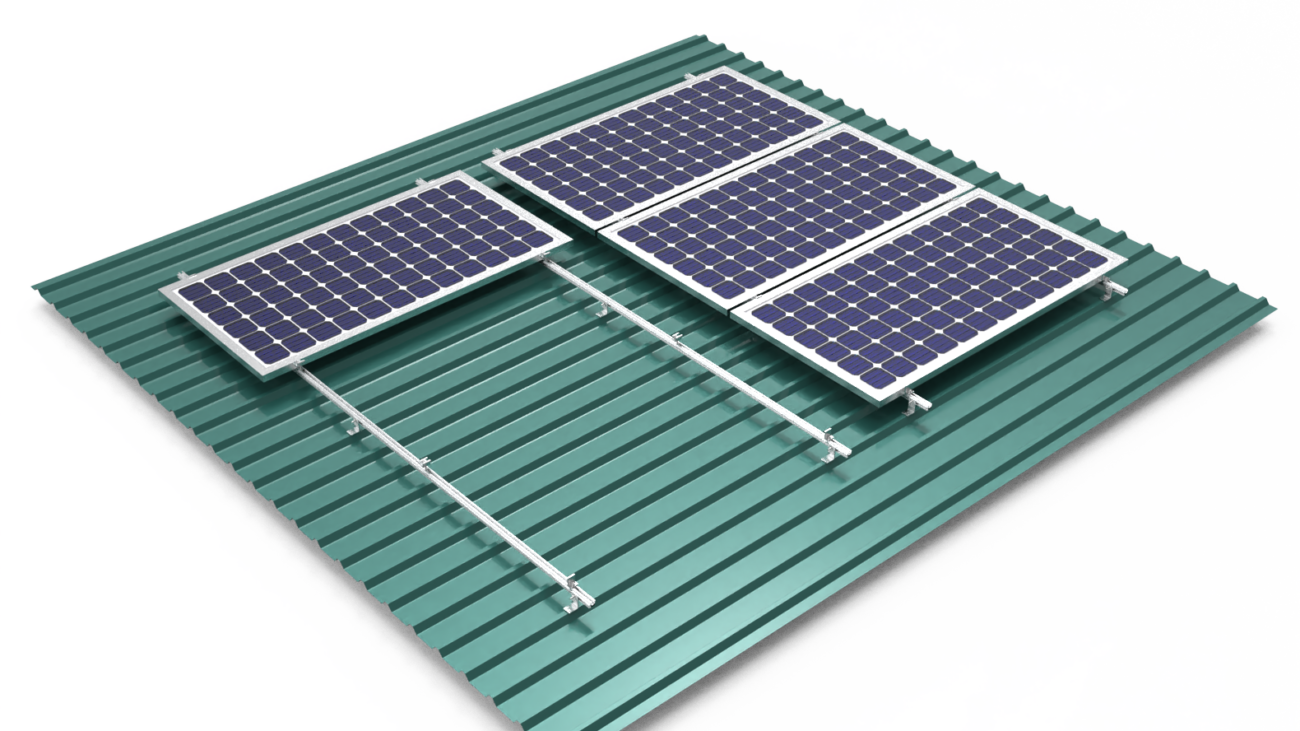

Residential, Commercial and Industrial

- Rooftop solar panels for homes, factories, offices

- Ground or pole mounted arrays

- Thermal properties aid efficiency

Carports and Building-Integrated

- Vehicle and parking shade structures

- Building facades, walls, rooftops

- Aesthetic finishes blend seamlessly

Ground Mount and Tracking

- Free standing arrays on ground bases

- Solar trackers following sun movement

- Resilience to outdoor exposure

Off-Grid Installations

- Remote cabins and rural areas

- Recreational vehicles and trailers

- Resistant to vibration and shock

Sustainability

- Recyclability makes suitable for green building

The lightweight yet durable anodized aluminum provides both structural integrity and design flexibility for solar panels across small scale residential to large commercial installations in diverse settings. It remains one of the most versatile and reliable solar infrastructure materials.

Let me know if you need any changes or elaboration on the highlighted applications. I aimed for brevity while including relevant keyword targets.

IV. Sustainability

Anodized aluminum stands out as an eco-friendly metal used for solar panel frames due to:

Recyclability and Reduced Waste

- Fully recyclable at end of product lifecycle

- Recycling requires little energy

- Reduces landfill waste

- Conserves bauxite ore resources

- Reusable without quality loss

Energy-Efficient Manufacturing

- Anodizing process consumes less energy

- Lower carbon footprint than other metals

- Process powered by renewable electricity

Anodized aluminum is aligned with solar energy’s sustainability goals. Key properties like:

- Corrosion resistance

- Strength and durability

- Thermal conductivity

Enhance lifespan, cutting replacement needs.

The combined qualities make anodized aluminum a standout green material for solar farm infrastructure. Its closed-loop recyclability and energy-efficient production supports renewable energy’s mission to reduce environmental impact.

V. Comparison to Other Frame Materials

Anodized aluminum stands out from other typical frame materials:

Galvanized Steel

- Heavier than aluminum

- Prone to rust and corrosion

- Higher maintenance costs

- Narrow aesthetic options

Stainless Steel

- More expensive

- Heavier than aluminum

- Limited decorative varieties

Composite Materials

- Durability issues in outdoor settings

- Can delaminate over time

- Shorter lifespan than aluminum

- Not easily recyclable

Anodized Aluminum Advantages

- Lightweight strength

- Resilience to extreme weather

- Excellent life cycle durability

- Ability to harmonize visually

- Sustainable properties

As a metal, anodized aluminum offers an optimal balance of strength, corrosion resistance, and recyclability – enabling more durable and eco-friendly solar panel infrastructure. Combined with flexibility in colors and textures, it remains a premium framing choice.

VI. Conclusion

Anodized aluminum stands as a top-tier solar panel framework option when key deciding factors around resilience, sustainability and aesthetics are considered.

Key properties like corrosion and abrasion resistance lend well to long-term use within hot, humid or coastal environments – while an efficient strength-to-weight ratio provides structurally sound support regardless of mounting variables across diverse solar farm, commercial building and residential settings on ground, rooftop or elevated installations.

Sustainability merits also rate highly – with superior recyclability, energy-efficient manufacturing processes and lifecycle durability that minimizes replacement needs – thus aligning well with renewable energy ideals.

Additionally, ability to colour and finish in a plethora of architectural styles empowers more seamless visual integration within different landscapes.

Compared against steel, composites and other customary building metals on vital metrics ranging from weather resilience to eco-friendliness – anodized aluminum garners excellent marks as a specialized solar panel framework, earning its classification as an optimal top choice for critical infrastructure across an array of solar energy project needs.