Introduction to EPDM Rubber

EPDM (ethylene propylene diene monomer) is a type of synthetic rubber that offers excellent performance properties that make it well-suited for use in solar panel mounting applications. EPDM stands out from other rubbers due to its:

- Durability

- Weather resistance

- Flexibility across a wide temperature range

- Chemical resistance

These characteristics allow EPDM rubber to withstand outdoor environments for many years without degradation.

EPDM contains three main components:

- Ethylene

- Propylene

- Diene

The diene facilitates sulfur vulcanization which enables crosslinking and gives EPDM its useful properties.

Key Properties

- Temperature resistance: From -50°C to +150°C

- UV radiation resistance

- Ozone resistance

Due to its saturated polymer backbone, EPDM vastly outperforms unsaturated rubbers in terms of resisting heat, light, and environmental damage over time.

| Property | Value |

| Thermal expansion | 160 μm/(m·K) |

| Max temperature | 150°C |

| Min temperature | -50°C |

Solar Panel Mounting Applications

In solar panel mounts, EPDM is used primarily for:

- Roof penetrations

- Prevents water leaks

- Protects electrical connections

- Gasket material

- Cushions and secures panels

- Absorbs vibration

Its water resistance and weather resistance makes EPDM the ideal sealant and protector for roof-mounted systems in rainy climates.

With proper EPDM accessories like rubber pads and adjustable clamps, solar installers can securely mount frameless solar modules without risk of cracking thin film PV panels.

Overall, EPDM rubber offers an optimal balance of critical performance properties to safely and reliably mount photovoltaic arrays exposed to harsh outdoor conditions

II. EPDM Properties and Benefits

EPDM rubber stands out from other rubber materials due to its exceptional weather resistance, durability, flexibility, chemical resistance and water resistance. These properties make it ideal for outdoor applications like solar panel mounting:

Weather Resistance

- Withstands UV radiation, ozone and weathering

- Saturated polymer backbone resists damage

- Maintains properties after years outdoors

Durability

- High temperature resistant up to 150°C

- Retains strength and shape

- Low temperature performance down to -40°C

Flexibility

- Remains flexible in extreme cold and heat

- Conforms to various shapes

- Absorbs vibration and shock

Chemical Resistance

- Resilient against acids, alkalis

- Withstands many harsh organic solvents

Water Resistance

- Waterproof and moisture-proof

- Prevents leaks, flooding and corrosion

- Protects electrical systems

These capabilities make EPDM ideal for:

- Roof penetrations

- Gasket material to secure panels

- Protecting outdoor electrical connections

With its balance of critical properties, EPDM rubber is the preferred material to safely install frameless solar modules and mount PV arrays in harsh climates.

III. EPDM Applications

With its excellent weather resistance, durability and flexibility, EPDM rubber is widely used in outdoor applications that require reliable water and air sealing properties.

Key applications include:

Solar Panel Mounting

- Roof Penetrations

- Flashings, collars and seals

- Prevents interior leaks

- Gasket Material

- Secures panels to mounts

- Absorbs vibration

- Protects components

Roofing Materials

- Rubber Roofing Panels

- Durable and waterproof

- Resists mold and rot

- Harnesses solar power

Accessories

- Rubber Pads

- Cushion clamps

- Protect thin film PV panels

- Module Clamp Rubber Strips

- Secures frameless solar modules

- Prevents glass cracking

Adjustable Clamps

- Safely secures uneven and curved surfaces

- Thermal expansion accommodation

- Compatible with 5-10 mm panels

Outdoor Enclosures

- Protects electrical boxes and gear

- Seals out moisture, dirt and debris

- Withstands weathering and UV rays

With EPDM’s balanced material properties, it serves critical sealing, mounting and protection functions across countless outdoor applications.

IV. EPDM in Outdoor Environments

EPDM’s exceptional resistance to heat, sunlight and environmental degradation makes it an ideal rubber material for permanent outdoor installation.

Temperature Resistance

- Withstands high temperatures up to 150°C

- Retains flexibility at low temperatures down to -50°C

- Handles extreme weather fluctuations

UV Resistance

- Specialized polymer backbone resists UV radiation

- Prevents material degradation

- Provides decades of exposure resistance

Ozone Resistance

- Additives block ozone degradation

- Prevents cracking and hardening

- Extends service life

Weathering Resistance

- Stands up to years of rain, sun and snow

- Retains a like-new appearance

- No visible signs of aging

Service Lifespan

- Properly formulated EPDM lasts for decades

- Far exceeds the capability of other rubbers

- Reduces the need for replacement

These capabilities make EPDM the preferred choice for:

- Roof seals

- Solar panel mounts

- Outdoor gaskets and seals

- Protecting components in harsh environments

EPDM rubber delivers reliable, long-lasting performance in even the most punishing outdoor installation environments.

V. EPDM in Solar Panel Mounting

EPDM’s exceptional durability and weather resistance makes it an ideal material for solar panel mounting applications.

Key Uses

- Roof Penetrations

- Flashings and seals

- Prevent leaks

- Gasket Material

- Cushion and secure panels

- Absorb vibration

Solar Mounting Accessories

- Rubber Pads

- Protect thin film PV panels

- Cushion adjustable clamps

- Module Clamp Rubber Strips

- Secure frameless solar modules

- Prevent glass cracking

Benefits

- Waterproof and moisture-proof

- Accommodates expansion and contraction

- Electrically insulating

- Resilient shock absorption

Adjustable Clamps

- Secure uneven and curved surfaces

- Compatible with 5-10 mm panels

- EPDM pads protect glass

Frameless Mounting

- Secure mounting without frames

- Rubber pads prevent damage

- Clamp securely without slipping

With its durability and sealing capability, EPDM rubber makes an ideal accessory material for safely and reliably mounting solar arrays on rooftops and carports while protecting them from weather events and mechanical stresses.

VI. EPDM Accessories

EPDM’s flexibility and durability make it an ideal material for accessories used to safely mount solar panels. Key accessories include:

Rubber Pads

- Cushion and protect panels

- Place inside clamps

- Prevent glass damage

- Available thicknesses:

- 5mm

- 10mm

- 15mm

Module Clamp Strips

- Created from extruded EPDM strips

- Protect frameless panel edges

- Offer cushioning and grip

- Lengths:

- 8cm

- 12cm

- 15cm

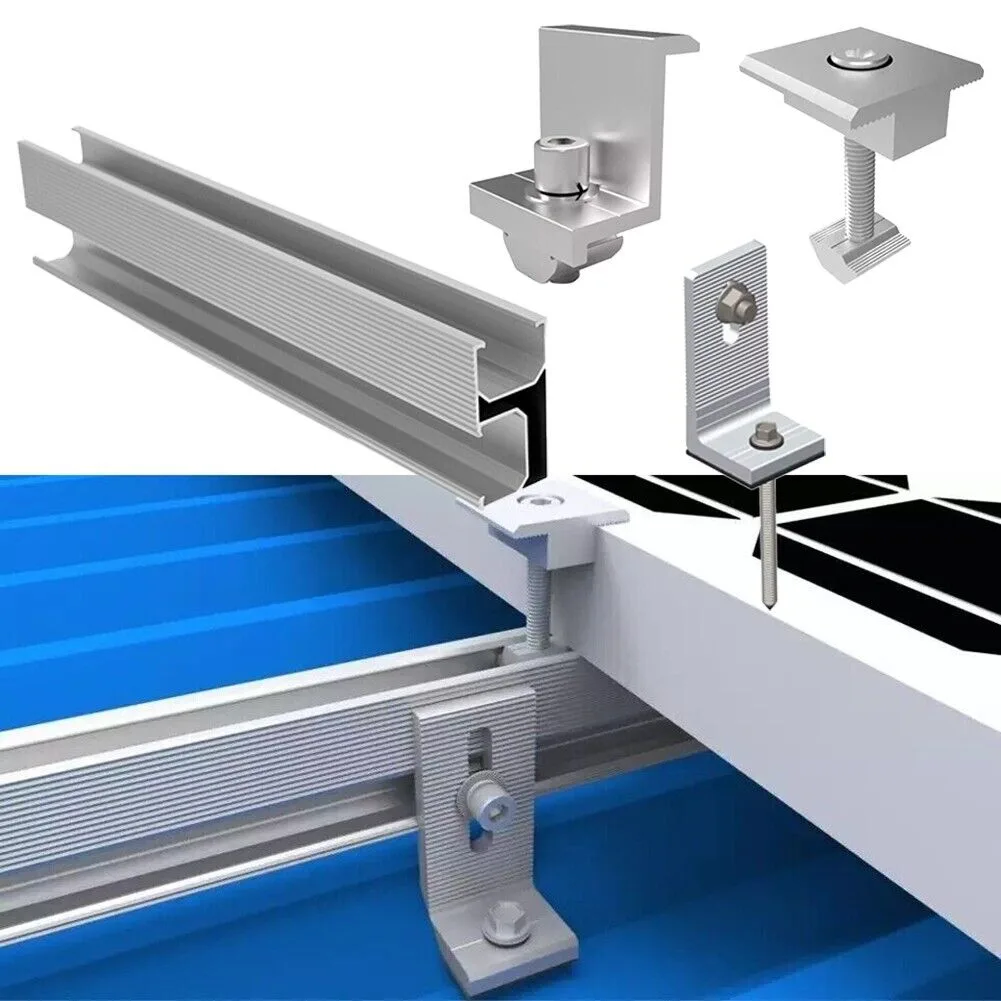

Adjustable Clamps

- Flashed aluminum clamps

- EPDM rubber inserts

- Secure uneven shapes

- Grip 5-10mm panels

Flashing Seals

- Seals roof penetrations

- Split EPDM boot design

- Prevents leaks

- Reusable and adjustable

Specialty Gaskets

- Seals electrical boxes

- Moisture and dust protection

- Custom shapes available

With its sealing properties and flexibility, EPDM enables solar installers to safely secure panels and protect components from weather and mechanical damage.

Conclusion

EPDM rubber offers an unmatched balance of properties that make it the ideal material for solar mounting applications. Key advantages include:

- Weather resistance – Withstands decades of UV, ozone, rain, snow and temperature extremes

- Durability – Retains properties after years of outdoor stress

- Flexibility – Remains flexible across a wide temp range

- Waterproof – Prevents leaks and flooding

- Chemical resistance – Withstands environmental pollutants

- Solar Mounting Uses:

- Roof penetrations – Flashings, seals and gaskets

- Gasket material – Secures panels, absorbs vibration

- Rubber pads – Inside adjustable clamps to protect glass

- Module clamp strips – Secures frameless solar modules

Out of all available rubber materials, properly formulated EPDM delivers the best assurance for long-term performance and reliability in the harshest outdoor environments.

With UV stabilizers and antioxidants, modern EPDM formulations resist degradation from heat, light and ozone for decades. Paired with adjustable clamps and compression seals, solar installers can securely mount PV arrays in all climates knowing the rubber gaskets will continue providing protection against the elements throughout the system lifetime.

EPDM rubber stands above other materials as the ideal choice for safely securing roof-mounted solar panel installations.