I. Introduction to Solar Mounting Structure Design

Structura Metal provide a solar mounting structure is a crucial component of any photovoltaic (PV) system installation. Furthermore, this structures purpose is to securely anchor the solar panels while distributing weight and allowing us to orient the panels at the optimal angle to maximize solar radiation capture.

When designing solar mounting structures, we must make the following key considerations:

- Building Specifications – age, roof type/condition, location.

- Climate Conditions – wind, snow loads.

- System Size and Components – number of panels, foundations.

- Accessibility for installation and maintenance.

- Safety standards and certifications.

There are two main categories of solar panel mounting structures are:

Rooftop Mounting Structures

Rooftop mounts support themselves using the building itself and are generally a lower-cost solution. Sub-types include:

- Rail-Based – panels clipped onto rails bolted into roof

- Rail-Less – panels bolted directly into roof

- Shared-Rail – rails are shared between panels

These can be used on both sloped and flat rooftops.

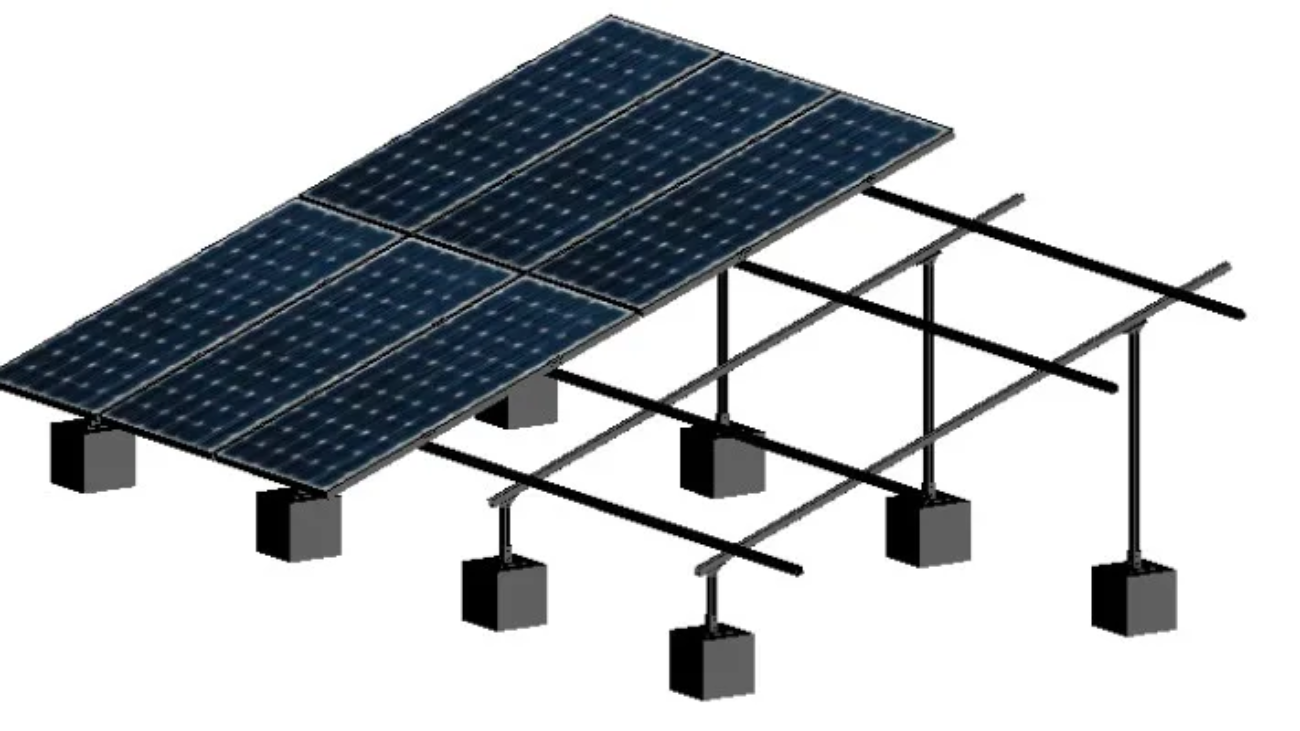

Ground-Based Mounting Structures

Ground mounts require foundations but allow more flexibility. Types include:

- Pole Mounts – structure with vertical pole anchored in concrete

- Foundation Mounts – vertical posts fixed in excavated foundations

- Tracking Mounts – structures with 1 or 2 axis tracking

| Mount Type | Pros | Cons |

| Rooftop | Lower cost <br> Use existing structure | Limited panels <br> Roof condition dependent |

| Ground | More panels <br> Flexible layout | Higher cost <br> Site prep required |

The mounting structure are also relies on the components like rails, brackets, anchors, and foundations to secure the panels.

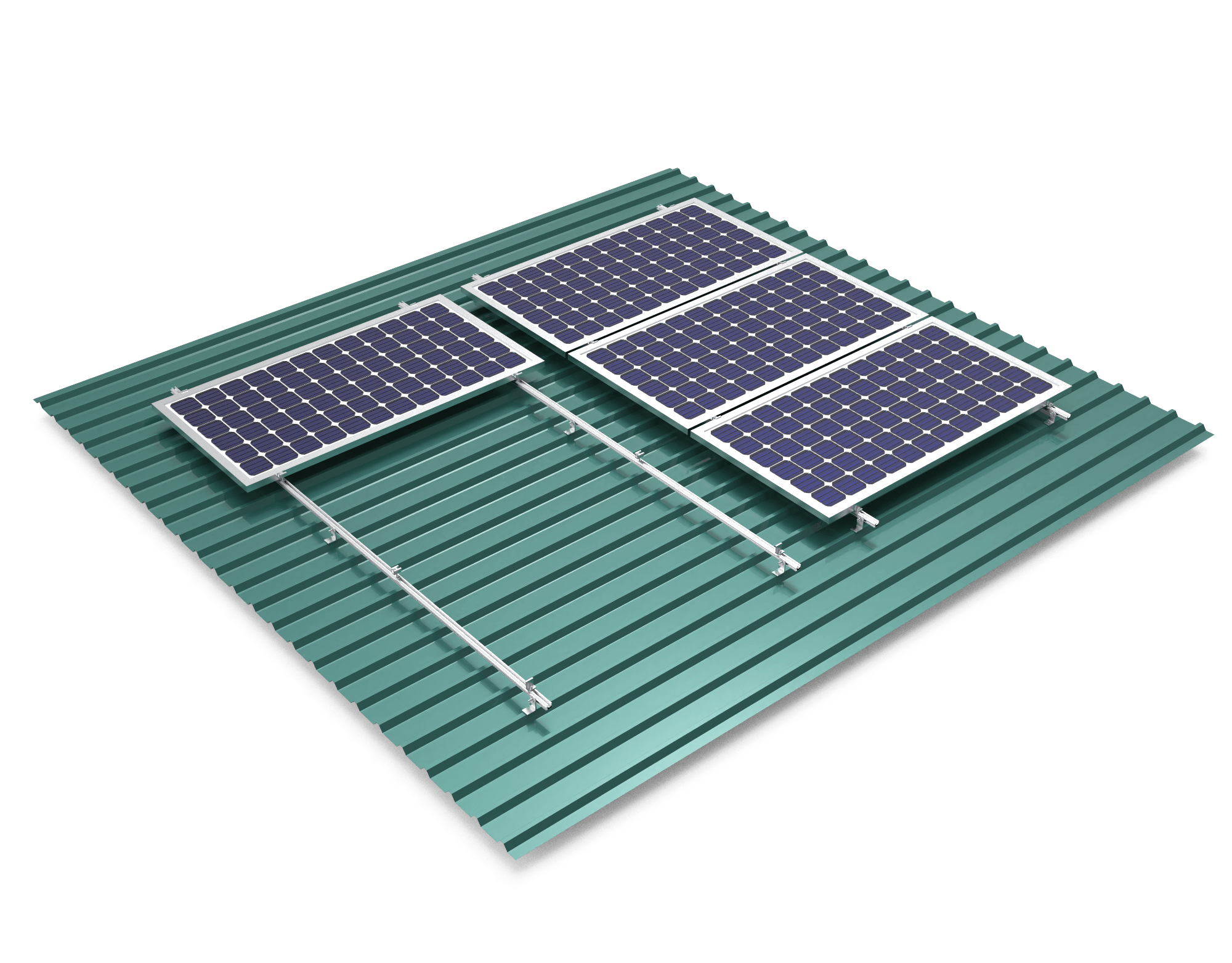

II. Rooftop Mounting Structures

Rooftop solar mounting structures attach directly to the roof surface, which helps to distributes weight and reduces costs by utilizing the existing structural support. The main types of rooftop mounts are:

- Rail-Based Mounting – Solar panels mount onto the rails that bolt into the roof. This is one of the most common rooftop solutions.

- Rail-Less Mounting – Panels bolt directly to the roof without rails. This reduces materials but requires more skill to install.

- Shared-Rail Mounting – Solar panels share common rails to reduce rail usage.

Rooftop mounts work for both sloped roof tilted designs and flat roof systems like commercial buildings.

Ballasted Footing Mounts made of concretes blocks help anchor flat roof structures without roof penetration. For pitched roofs, rail-based mounts orient panels at slopes matching the existing roof, while rail-less systems mount the panels in flexible tilted angles.

| Type | Description | Considerations |

| Rail-Based | Panels clip onto roof-bolted rails | Most common <br> Easy to install |

| Rail-Less | Direct panel roof mounting | Lower cost <br> Requires skill |

| Shared-Rail | Panels share common rails | Reduces rails <br> Optimizes installation |

| Ballasted | Concrete block anchors | No penetration <br> For flat roofs |

Proper Mounting Structure Design distributes panel weight, resists wind/weather elements, and orients panels properly on the roof.

III. Ground-Based Mounting Structures

Ground-mounted solar structures are anchored into the ground itself, providing more flexibility than rooftop solutions. Key types of ground mounts include:

- Pole Mounts – A simple steel pole and concrete anchor drilled into the ground can support smaller solar panel installations.

- Foundation Mounts – Vertical posts or pipes are fixed in concrete foundations requiring excavation and soil analysis.

- Tracking Mounts – Structures with the integrated 1 or 2 axis tracking capability to optimize solar radiation capture.

Multi-pole Mounting utilizes multiple vertical pipe supports to extending in a horizontal line to allow the scaling of larger installations.

The Smart Flower is a compact new solution resembling an opening flower with the integrated tracking solar “petals” for high efficiency generation.

| Type | Pros | Cons |

| Pole Mounts | Lower cost <br> Simple install | Small systems <br> Soil dependent |

| Foundation Mounts | Larger systems <br> Adjustable tilt | High cost <br> Site prep required |

| Tracking Mounts | Increased energy yield <br> Automated sun tracking | Complexity <br> Higher cost |

With ground mounting, factors like soil conditions, wind loads, and frost line depth inform needed foundation specifications. Integrated cable trays and wire runs should also be incorporated into the structural design.

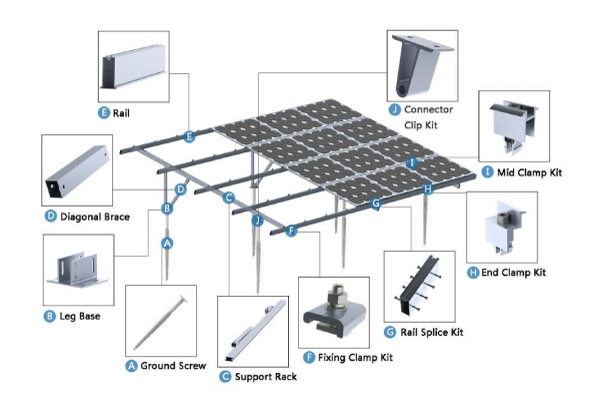

IV. Mounting Structure Components

In addition to the main structure frames, solar mounting systems rely on components like rails, brackets, clamps, and anchors to secure panels and transmit loads.

- Rails & Strut Channels – Horizontal rail structures and strut channels, often aluminium or galvanized steel, provide intermediate support and panel mounting points.

- Brackets – Adjustable bracket structures attah to rails to angle panels at the optimal tilt.

- Clamps – End and mid-clamps tightly affix panels along their edges and prevent slippage.

- Anchors & Foundations – Ground screws, anchor bolts, concrete piers and more keep the mounting frame fixed in place.

Wiring trays and cable management components are also integrated into the composite mounting unit.

| Component | Composition | Purpose |

| Rails | Aluminium, steel | Panel support & mounting points |

| Brackets | Stainless steel | Secure and tilt panels |

| Clamps | Aluminium | Grip panel edges |

| Anchors | Galvanized steel | Fix structure to roof or ground |

Proper specification and structural analysis ensures components can withstand anticipated wind, snow loads and thermal stresses across the system’s life.

Regular re-torquring of bolts and monitoring of components for issues like corrosion is key for longevity.

V. Structural Considerations

Careful analysis of building specifications and site conditions informs the customized structural design of solar mounting systems. Key factors include:

- Building Age & Type – The roofing substrata must have sufficient integrity to withstand panel loading. Older or weaker structures may have lower weight tolerances.

- Roof Accessibility – Installers will require safe access routes to the roof location that can accommodate components and tools.

- System Layout – Allowances must be made for positioning of all structural elements, panels, inverters and related components.

- Shading – Nearby structures or roof elements that could cast shadows on panels should be considered.

- Weather Loads – Snow, wind and rainfall levels determine design wind and snow load requirements.

- Soil Conditions – For ground mounts, soils must be evaluated for suitability to anchor foundation components.

| Consideration | Factor | Effect |

| Building Type | Material strength <br> Roof pitch | Weight limits <br> Mounting options |

| Accessibility | Pathways <br> Safety | Installation <br> Maintenance |

| Shading | Nearby structures <br> Roof elements | Solar interruption |

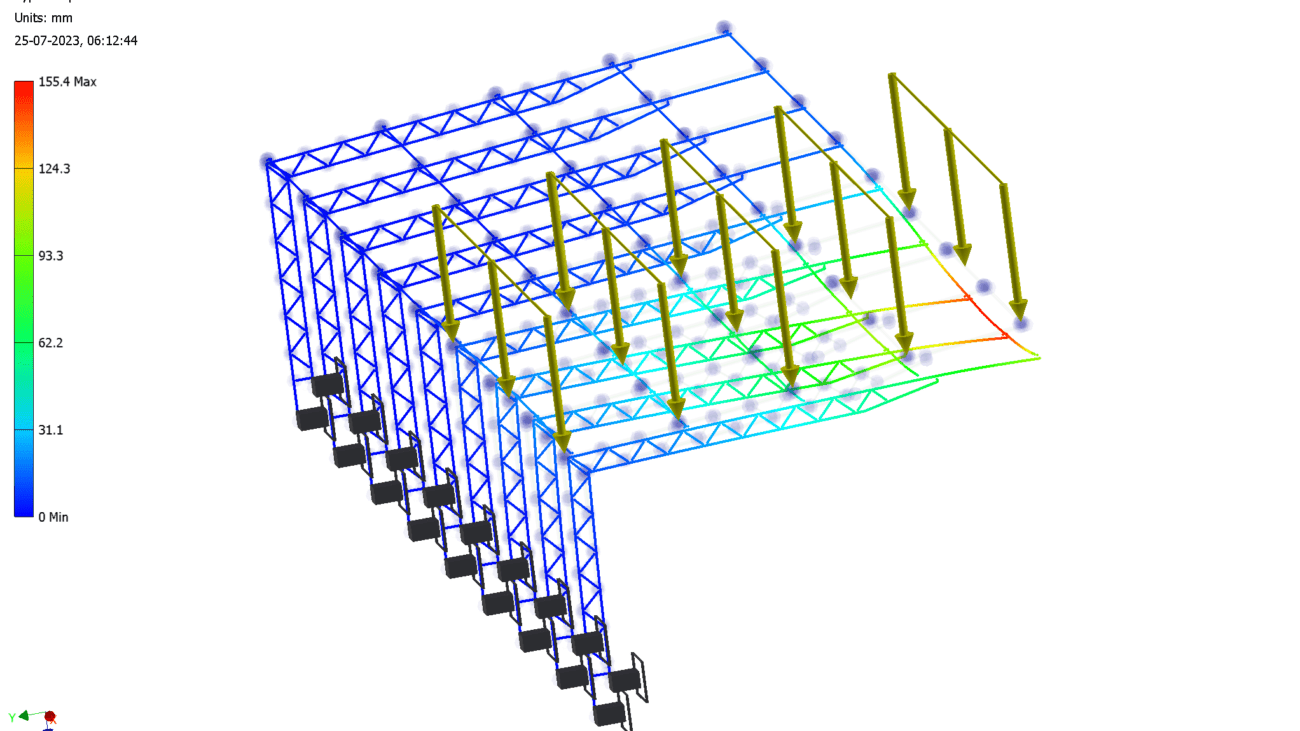

Analysis software models these parameters to tailor optimized, code-compliant mounting structural specifications.

VI. Analysis and Reporting

Detailed structural analysis and reporting ensure solar mounting systems meet safety and performance standards throughout their 25+ year lifetimes.

- Software Modeling like STAAD analysis the building specs, layouts, component ratings and environmental factors to engineer code-compliant mounting specifications.

- Structural Reports document all structural design elements, recommended hardware specifications, layouts, and electrical component integration guidance.

- Installation Manuals provide step-by-step mounting and wiring instructions for field implementation.

| Deliverable | Contents | Value |

| Structural Report | Specifications <br> Layouts <br> Hardware details | Customized design basis |

| Installation Manual | Mounting instructions <br> Electrical layouts | Correct field implementation |

Through reporting and guidelines empower the proper system installation and inform ongoing maintenance requirements like bolt re-torquing for maximum safety and energy production.