Solar Mounting Structures, also known as solar racking systems, are an essential component of any solar energy system. They provide the support and stability necessary for solar panels to function effectively and efficiently. In this report, we will provide an introduction to the basics of solar mounting structures, including the different types of systems available, the materials used to construct them, and the key considerations when designing and installing a solar mounting structure.

Types of Solar Mounting Structures

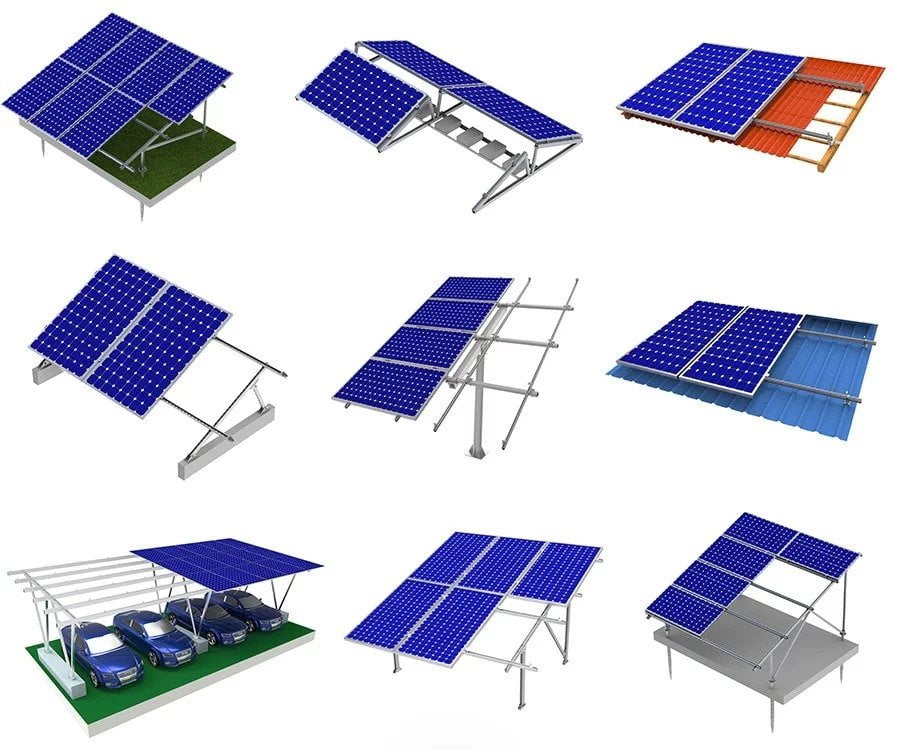

There are several different types of solar mounting structures available, each with their own unique features and benefits. The most common types include:

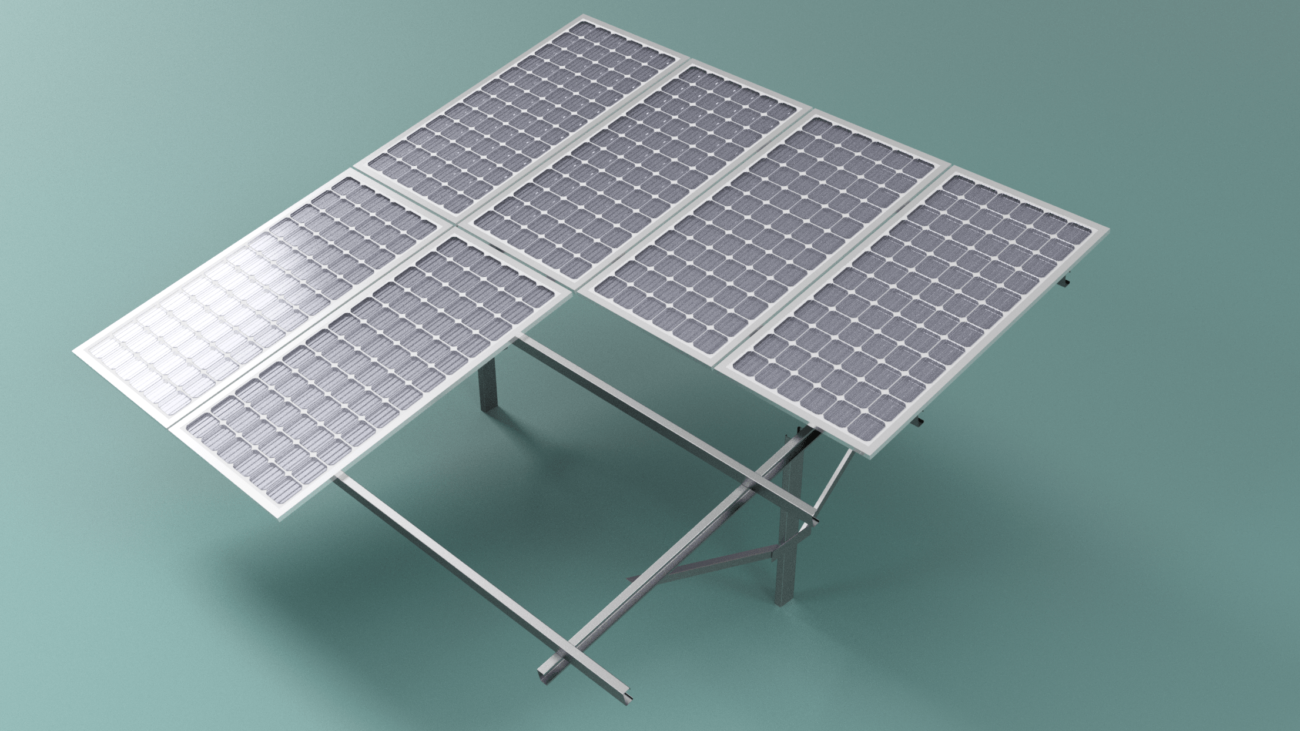

- Ground-Mounted Systems: These systems are installed directly on the ground and are typically used for large-scale solar projects, such as utility-scale solar farms. Ground-mounted systems are highly customizable and can be designed to meet specific site requirements.

- Roof-Mounted Systems: These systems are installed directly on the roof of a building and are commonly used for residential and commercial solar projects. Roof-mounted systems are available in a variety of styles, including flush-mounted, ballasted, and penetrating systems.

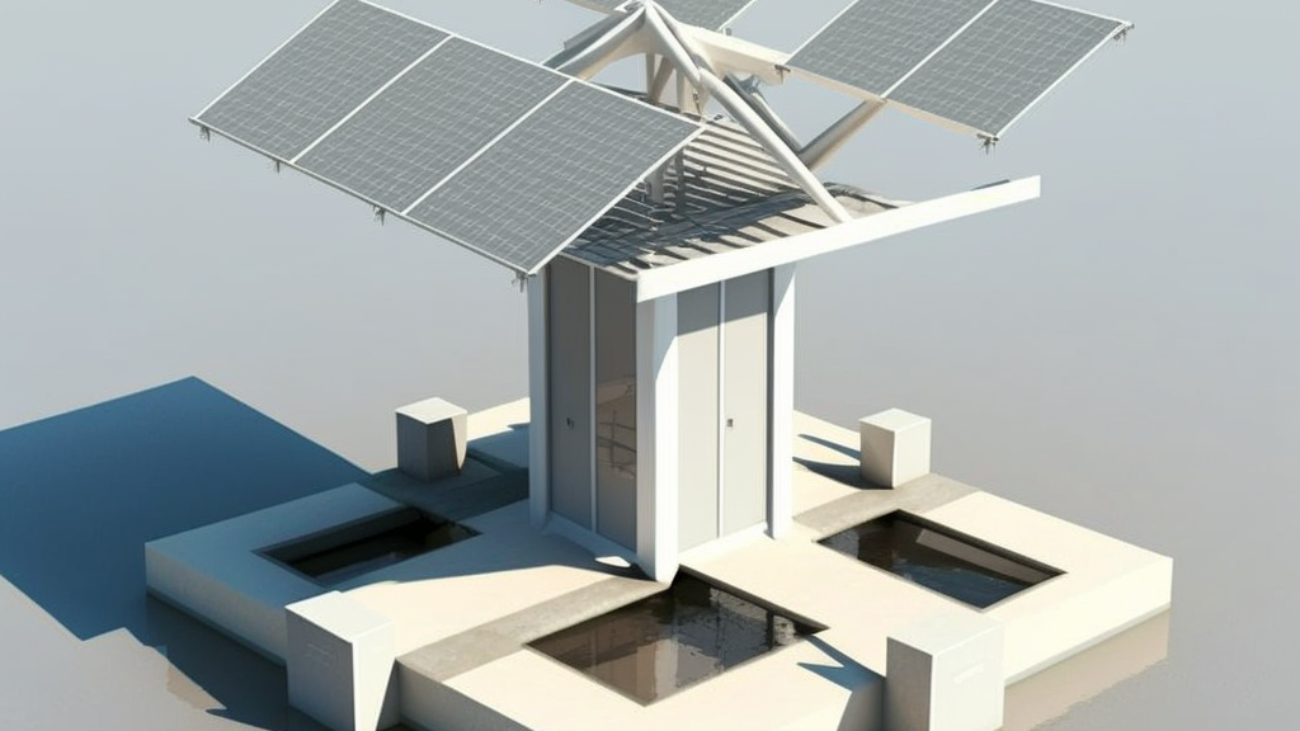

- Floating-Mount Systems: As their name suggests, these mounts are designed to float on water, making them ideal for installations on lakes and other bodies of water. Floating mounts are typically constructed of plastic or polymer, and they are designed to securely hold the solar array in place while also allowing for a certain amount of flexibility.

Materials Used in Solar Mounting Structures

The materials used to construct solar mounting structures are typically aluminum, steel, or a combination of both. Aluminum is a popular choice due to its lightweight, corrosion-resistant properties. Steel is also commonly used, particularly for ground-mounted systems, due to its strength and durability. Both materials can be coated with a variety of finishes to protect against weathering and corrosion.

Key Considerations When Designing and Installing a Solar Mounting Structure

When designing and installing a solar mounting structure, there are several key considerations that must be taken into account. These include:

- Site conditions: The solar mounting structure must be designed to withstand the specific site conditions, such as wind, snow, and seismic activity.

- Load capacity: The solar mounting structure must be able to support the weight of the solar panels and any additional equipment, such as inverters and batteries.

- Orientation and tilt: The solar mounting structure must be oriented and tilted to optimize solar panel performance and maximize energy production.

- Accessibility: The solar mounting structure must be designed to allow for easy access for maintenance and repairs.

In conclusion, solar mounting structures are an essential component of any solar energy system, providing the support and stability necessary for solar panels to function effectively and efficiently. Understanding the different types of systems available, the materials used to construct them, and the key considerations when designing and installing a solar mounting structure is important for ensuring the success of any solar project.