I. Introduction to GI Structures

In Structura Meta our GI (Galvanized Iron) structures have become increasingly popular for mounting solar PV systems in recent years. They provide an effective, durable, and cost-effective solution for both residential and commercial solar installations.

Galvanized iron is an iron or steel material coated in zinc to prevent corrosion. The galvanization process involves dipping the iron in molten zinc to form a protective coating. This coating allows GI structures to withstand outdoor elements and last for decades.

Some key benefits of using GI structures for solar PV systems:

- Cost Effective – Galvanized iron is relatively inexpensive compared to aluminium or stainless steel. This makes GI mounting structures very affordable.

- Low Maintenance – The galvanized coating prevents rust and corrosion, even in harsh environments. This results in a long service life with minimal maintenance required.

- Strong and Durable -The Galvanized Iron has high tensile strength making it resistant to warping, bending or breaking. GI mounting structures can withstand heavy wind loads.

- Lightweight – Our Galvanized Iron is lighter than the other metals. This makes GI structures easier to transport and install.

- Customizable – Our Galvanized Iron structures can form into a variety of shapes and sizes. GI mounting structures can design for the specification.

Our Galvanized Iron structures are suitable for both the ground mount and rooftop solar installations. For ground mounts, we anchor the structures into the ground to hold the solar modules at the optimal angle. For rooftop systems, we mount the structures into the roof without penetrating the surface.

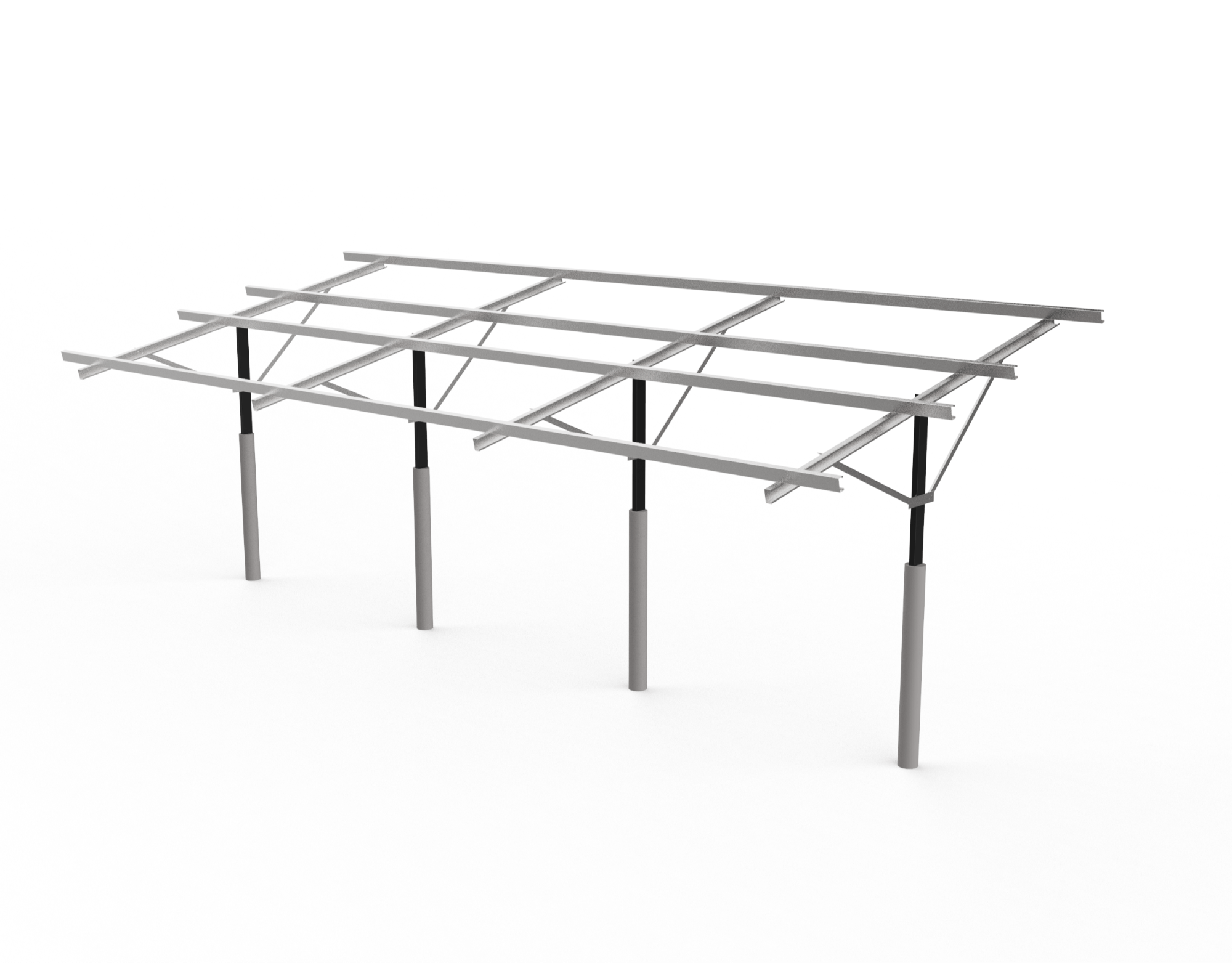

The main components of a GI solar mounting structure include:

- Rails – horizontal members that modules attach to

- Legs – vertical supports that connect to rails

- Brackets – connect rails to legs

- Fasteners – bolts, clamps, screws to connect components

II. Benefits of Using GI Structures

Our GI structures provide numerous benefits that make them well-suited for solar PV mounting systems:

- Cost Effective – Our Galvanized Iron is more affordable than other metals like aluminum or stainless steel. This results in lower material costs for the mounting structure.

- Long Life – The galvanized coating protects the underlying steel from corrosion and rust.

- Additionally, this allows GI structures to last for decades with minimal maintenance.

- Lightweight – Our Galvanized Iron is lighter than materials like concrete or steel. This makes GI:

- Easier to transport and handle

- Requires less robust roof structures

- Simpler installation process

- Strength – Our Galvanized Iron has high tensile strength. It can withstand heavy wind and snow loads.

- Customizable -We can bend and form it into many shapes.

- Specific solar modules

- Uneven terrain

- Unique mounting requirements

- Faster Installation – The modular design allows for rapid on-site assembly. This results in lower labour costs.

Our Galvanized Iron mounting structures are an attractive solution due to their durability, strength, customizability, and affordability. Their advantages make Galvanized Iron a popular choice for residential and commercial solar installations.

III. Ground Mount vs Rooftop Mount

We utilize our structures for both ground and rooftop solar mounts. There are pros and cons to each mounting method:

Ground Mount

- Not limited by roof size/orientation

- Access to more sunlight

- Greater control over tilt angle for optimal orientation

- Requires land area

- More exposed to weather and potential tampering

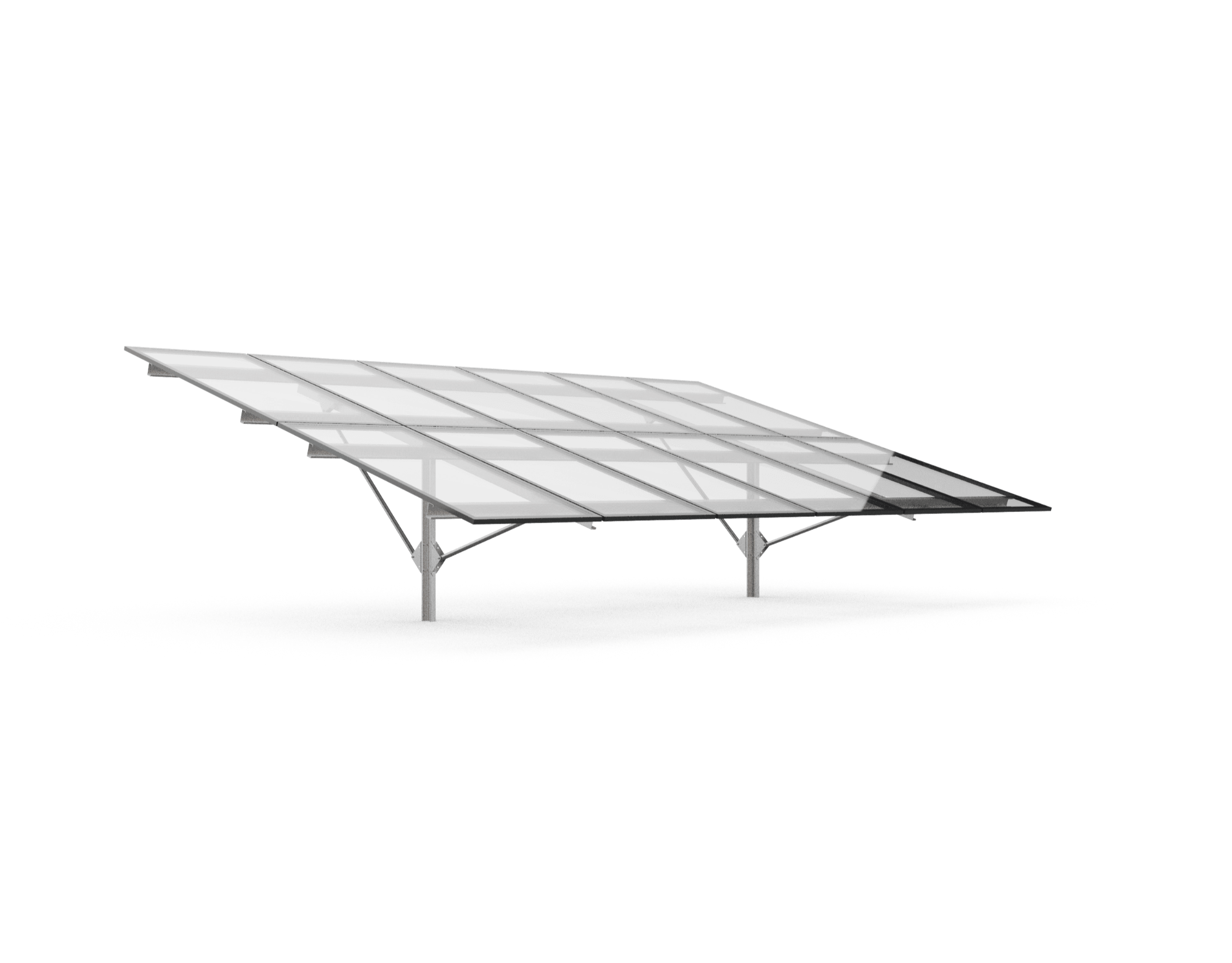

Rooftop Mount

- Makes use of unused roof space

- No land requirements

- Can be parallel to roof surface or titled

- Limited by roof size and orientation

- Extra weight and forces on roof structure

- Height restrictions may limit sunlight access

Tilt Angle

- Seasonally we easily adjust the tilt angle for ground mounts.

- Rooftop mounts limited by fixed roof angle and height restrictions

- Optimal tilt angle oriented to maximize annual solar radiation

Orientation

- Rooftop mounts restricted by roof’s orientation

- We align ground mounts to the optimal south-facing orientation.

Our Ground mounting structures are best for larger systems where space allows. Rooftop mounting maximize unused roof area, but have more limitations. Proper site analysis and mounting design help maximize productivity for either mounting method.

IV. Environmental Factors

GI mounting structures are designed to withstand decades of the exposure to harsh environmental conditions. Key features enabling them to endure these factors:

- Corrosion Resistant Coating – The zinc galvanized coating protects the steel beneath from oxidation and rust. This allows the structures to resist degradation in wet and humid environments.

- Wind Load Resistance – GI structures are engineered to the withstand hurricane-force winds. Key factors include:

- Cross-bracing for lateral stability

- Secure anchoring to foundations

- Robust structural members

- Snow and Ice Buildup – The structural members are designed to support expected snow/ice loads for the installation locale.

- Thermal Expansion – Temperature fluctuations cause expansion/contraction of metal. GI mounting components are designed with the sliding connections to accommodate this movement.

- Drainage – Water drainage pathways prevent pooling and minimize runoff erosion.

- Resilient Joints – Allows flexing to prevent fatigue failures.

Our regular inspection and maintenance help prevent and identify weathering issues before they cause structural failures. Overall, Galvanized Iron structures provide decades of durable service in harsh outdoor environments when properly designed and installed.

V. Customizable Structures

“Structura Metal” gives a key advantage of GI for solar mounting is the ability to customize the structural design for specific installation requirements:

- Site Conditions – We configure the modular Galvanized Iron components for optimal mounting for the terrain and layout.

- Sloped sites

- Rocky/uneven ground

- Working around existing structures

- Lightweight Options – For rooftop installations with weight limitations, GI can be designed with the smaller profiles to the minimize dead loads.

- Wind Loads – The post embedment depths can be adjusted to meet the expected wind speeds.

- Snow Loads – Designs can account for expected snow and ice buildup loads.

- Orientation – The Components can be arranged for optimal tilt angle and south-facing orientation.

- Access and Walkways – Integrated steps, ladders, and catwalks can be incorporated for the access and the maintenance.

- Aesthetics – Color, shape, and finish allow GI structures to blend into the surroundings.

Structura manufactures the products as per the customizable nature of GI allows creating an ideal, site-specific mounting solution. Professional engineering expertise helps optimize the structural design to meet the installation’s unique specifications, loads, and challenges. The result of mounting system tailored specifically for the project site and conditions. This flexibility gives galvanized iron structures an advantage over pre-fabricated, one-size-fits-all mounting products.

VI. Ease of Installation

There is benefits of a proper engineered Galvanized Iron mounting system is ease to installation:

- Modular Design – The structures consist of discrete components like rails, posts, and brackets. These bolt together on site for straightforward assembly.

- Lightweight – Compared to concrete or steel, the relative lightness of GI makes components easier to handle and install.

- Minimal Equipment Needed – Basic tools like wrenches, drivers, and cordless tools are all that’s needed for the most installations. No heavy equipment required.

- Rapid Assembly – The simplicity of the components enables efficient installation. A small crew can completely install a ground mount system in days rather than weeks.

- Minimal Site Disturbance – Pre-engineering allows precise excavation for foundations, minimizing ground disturbance.

- Leveling Not Required – Uneven sites don’t impede installation. The post foundations can vary in depth as needed.

- Straightforward Layout – The modular design makes it easy to ensure proper spacing, row alignment, and tilt angles.

- Roof Integration – Roof mounts can be efficiently attached to the existing rafters without penetrating the roof surface.

Proper planning, layout, and installation best practices ensure the GI mounting system goes together smoothly. The result is maximizing productive on-site labour time and rapid solar array assembly.

VII. Types of GI Materials

There are a few key types of GI materials used for solar mounting structures:

- Hot-Dip Galvanized Steel – The most common type. Steel is dipped in the molten zinc to bond a protective coating to the surface. Provides long-term corrosion resistance.

- Electrogalvanized Steel – Uses an electroplating process to apply a thin zinc coating. More uniform coating but less corrosion protection than hot-dip galvanizing.

- Galvalume – A proprietary GI material. Contains a blend of zinc and aluminium for improved corrosion resistance compared to galvanized steel.

- Galfan – A zinc-aluminium alloy coating applied via a hot-dip process. Provides enhanced anti-corrosion properties.

| Material | Description | Corrosion Protection |

| Hot-Dip Galvanized | Zinc coating from dipping in molten zinc | Excellent |

| Electrogalvanized | Zinc coating from electroplating process | Moderate |

| Galvalume | Zinc-aluminum alloy coating | Very Good |

| Galfan | Zinc-aluminum alloy coating from hot-dip process | Excellent |

The optimal choice depends on factors like cost, lifetime, and environment. Hot-dip galvanizing provides the best all-around corrosion protection. Galvalume and Galfan offer improved longevity in harsh coastal or industrial environments. Consult with an engineer to select the ideal GI material.

VIII. Conclusion

Our GI mounting structures provide an attractive solution for solar PV systems. Key benefits make them a popular choice:

- Cost-effectiveness – Furthermore, GI is more affordable than other metals. This provides savings on materials.

- Durability – Galvanization gives excellent corrosion resistance and decades of maintenance-free service life.

- Strength – High tensile strength enables Galvanized Iron to withstand heavy wind, snow, and ice loads.

- Light Weight – Easier transportation, handling, and installation compared to heavier structures.

- Customizable – Galvanized Iron can be formed into site-specific designs to account for the unique requirements.

- Quick Installation – The modular system allows rapid on-site assembly, saving time and labour.

- Low Maintenance – Once installed, GI requires little ongoing maintenance.

In Structura proper designing and engineering, Galvanized Iron mounting structures present an optimal balance of strength, longevity, reliability, and affordability. Their advantages make them a smart, low-risk choice for securing solar PV systems in any environment. Galvanized Iron delivers proven performance at a competitive price point.