MS C Channel for Solar Mounting System

Structura Metal introduce the “Mild steel (MS) C channels” are an optimal structural framing solution for mounting and supporting solar photovoltaic (PV) modules in utility-scale solar farms and the roof-top solar installations.

MS Channels offer several key advantages that make them suitable for solar structures compared to other materials:

Structural Properties

- High strength-to-weight ratio – light enough for easy to handling and transportation.

- Resistant to significant wind, seismic and live loads.

- Easy to customize and design mounting structures.

- Can span larger distances by avoiding intermediate supports.

- Enable quick on-site assembly using bolted connections.

Durability and Corrosion Resistance

- Hot-dip galvanized steel provides long term corrosion protection.

- Stainless steel channels deliver 30+ years maintenance-free service life.

- Withstand outdoor exposure to sun, moisture, wind, soil.

Cost Efficiency

- Lower initial raw material cost compared to aluminum sections.

- Saves overall PV system cost through structural optimization.

- Faster project execution leads to reduced installation expenses.

Sustainability

- Steel is 100% recyclable material.

- Produced from up to 90% recycled the scrap content.

- Cuts carbon footprint versus other structural framing options.

Configurability and Integration

- Seamlessly accepts all common PV module configurations.

- Compatible with tracking systems to further boost energy yield.

- Integrates well with site electrical cabling and equipment

C channels provide excellent dimensional stability and load carrying capacity to securely mount solar panels for 25+ year life spans.

Key Loads and Design Considerations

PV mounting structures are designed to withstand various loads as per relevant regional structural design standards. Some key considerations are:

Dead Loads

- Self-weight of PV modules, channels, fasteners.

- Solar electrical components like inverters.

Wind Loads

- Uplift and lateral forces from wind pressures.

Seismic Loads

- Earthquake zone classifications.

- Horizontal and vertical seismic coefficients.

Snow Loads

- Vertical pressure from accumulated snow

- Downward and uplift forces.

Thermal Loads

- Thermal expansion of long channel runs.

Proper structural engineering ensures mounting frames have adequate strength, stiffness and stability against the worst-case combination of the above loads over the system life.

Mounting System Types

MS C Channels can be deployed across all common solar mounting configurations:

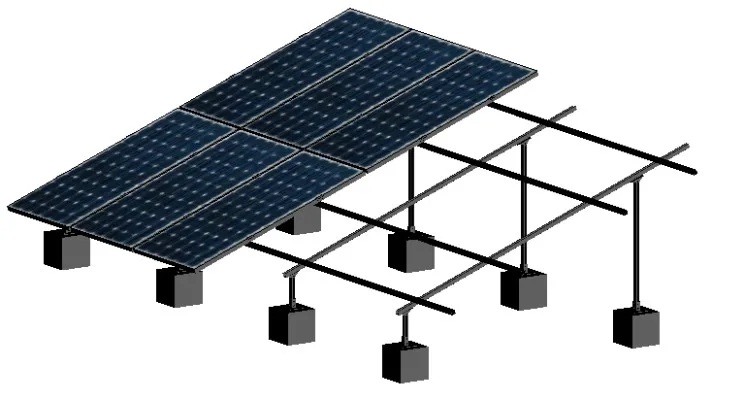

Ground Mounts

Free-standing metal structures mounted directly on the ground to elevate solar modules.

Benefits:

- Flexible layout options.

- Easy cleaning and O&M access.

- No roof structural modification.

Elevated Mounts

Frameworks raised above ground level on rammed piles to increase height above ground.

Benefits:

- Clearance above vegetation/buildings.

- Avoid shading obstructions.

- Improved air circulation.

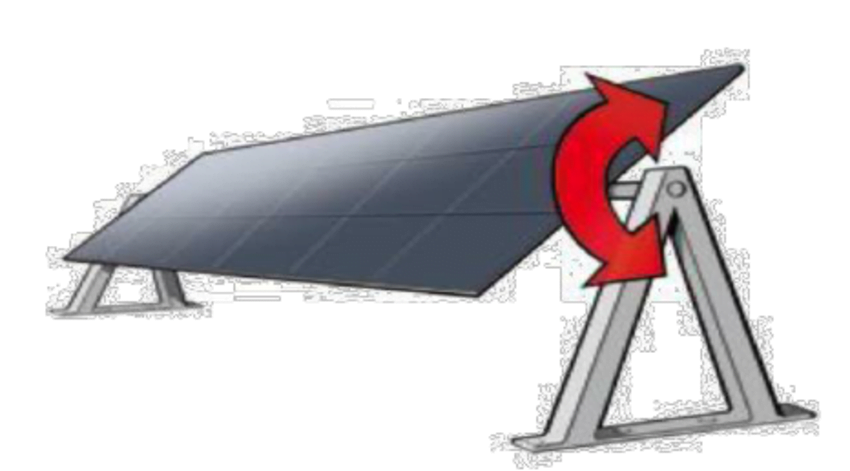

Single-Axis Trackers

Motorized MS channel mount structures rotating panels to track sun.

Benefits:

- Up to 30% higher energy yield.

- Improved early morning / late afternoon output.

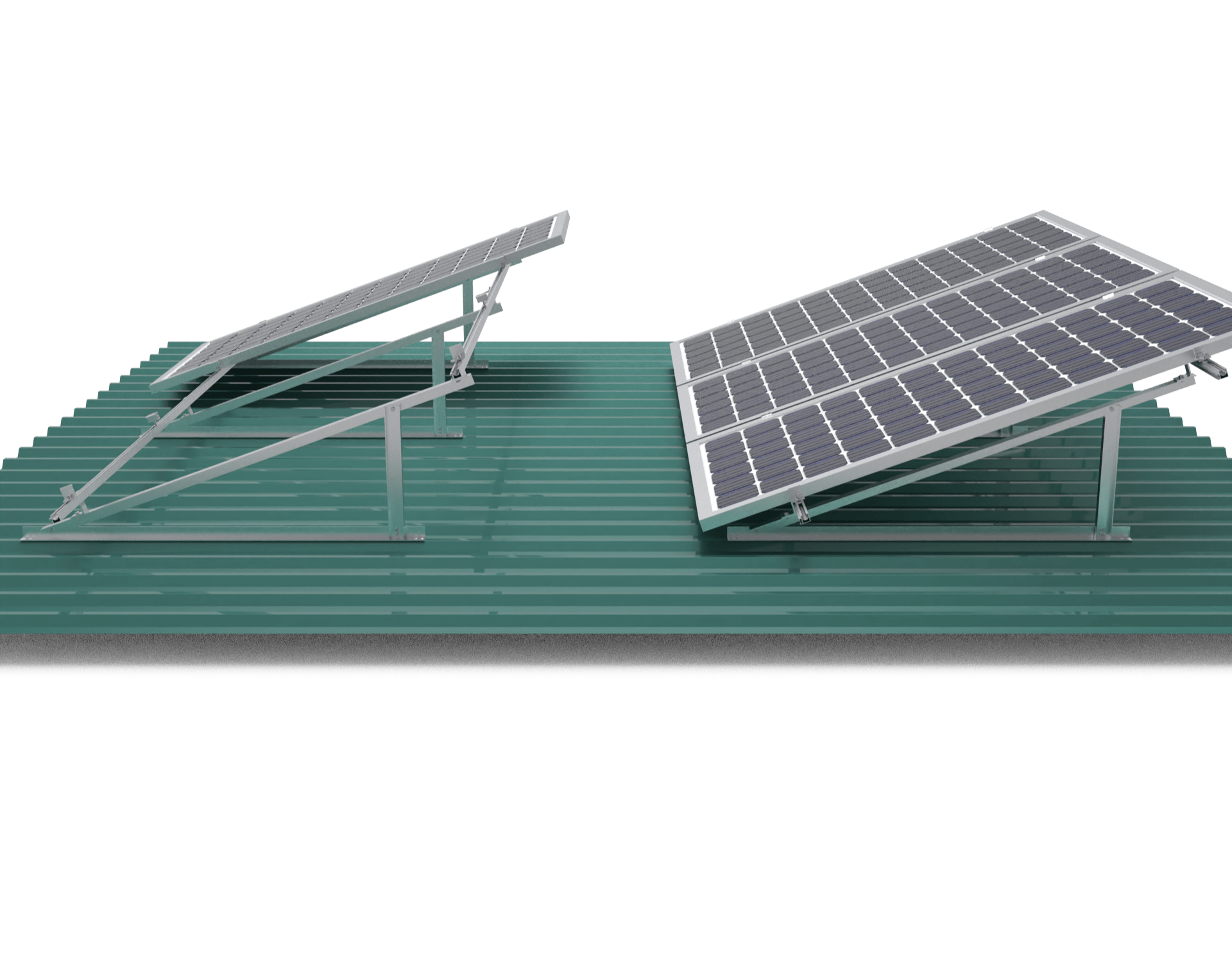

Roof Mounts

MS C Channel racking fixed directly above roof surface without penetrations.

Benefits:

- Versatile for pitched/flat commercial roofs.

- Avoid expensive structural reinforcements.

Carport Systems

Dual-use structures with integrated elevated PV arrays.

Benefits:

- Dual land utilization.

- Lower operating temperature.

Structural Customization

Engineers optimize PV mounting design by modeling site parameters and selecting suitable channel sections:

| Type | Thickness (mm) | Height (mm) | Typical Use |

| Light C Channel | 3-5 | 75-150 | Module clamping rails |

| Medium C Channel | 4-8 | 150-250 | Main purlins, girts |

| Structural Hollow Sections | 4-10 | 76-300 | Vertical posts, braces |

In Structura Metal having the other rolled steel sections like angles, tubes can be integrated with designed fabricated sections.

Suitable connection methods like bracketing, bolting and welding selected.

Hence MS C channels provide flexible, efficient design options for securing solar modules aligned with site requirements.

Channel Structural Behaviour

Steel channels have inherent structural efficiency characteristics:

The rectangular hollow cross section allows channels to:

- Carry substantial vertical and horizontal loads in two directions.

- Resist buckling and bending forces.

- Provide lateral and torsional stability to compression elements.

- Flanges connected by web efficiently spread stresses uniformly. This prevents failure by shear or excessive deflection.

- For solar structures, MS channels are normally oriented vertically to maximize load capacity along the direction of the web. This allows the flanges to effectively transfer wind/seismic pressures into the end connections.

- By combining back-to-back channel sections, very large bending moments can be accommodated without buckling risk.

Structural Analysis

The structural feasibility of the entire solar farm support structure with integrated MS C channels is validated under worst-case load combinations through advanced Finite Element Analysis simulations.

This confirms:

- Structural stability and strength.

- Maximum stresses and deflections are within limits.

- Adequate safety factor over required design life.

Any weaknesses detected can be mitigated by tweaks to the channel selection or support layouts.

Corrosion Protection

For steel structures installed outdoors, corrosion protection is vital for durability over 25 years.

Hot-dip galvanizing is applied to all MS C channel solar mounting frames for long term corrosion resistance.

The complete channel component is dipped in a bath of molten zinc which alloyed completely to form a protective coating.

Key benefits versus paints/coatings:

- Totally bonds with steel for lifetime corrosion protection.

- Withstands outdoor weathering without degrading.

- Minimal maintenance needed.

In our system the coloured powder coating can provide improved aesthetics and UV-resistance.

Hence hot-dip galvanized mild steel channels provide solar farm developers with a highly durable, low maintenance mounting system capable of handling all structural loads reliably over 25+ year lifespans.

The inherent advantages of steel C channels make them a Smart Structural and Value Engineering (SSVE) choice for large solar PV farms.