I. Introduction to Standing Seam Metal Roofs

A. Popularity and Benefits

Standing seam metal roofs (also known as seam roofs) have increased in popularity for pitched roofs, especially in the educational and leisure sector. Seam roofs are commonly made from steel, aluminium, and zinc. Key benefits include:

- Aesthetically pleasing look

- Robustness and weatherproof qualities

- Cooling effect from reflective coating, reducing energy use by up to 20%

These benefits complement solar PV mounting systems extremely well.

There are several major standing seam manufacturers, producing various seam types:

- Straight or round folds

- Single or double folded

| Seam Type | Description |

| Straight | Evenly spaced flat seams |

| Round | Curved seams |

| Single | One fold |

| Double | Two folds |

The seams are secured to the purlins using clips, allowing the panels to move freely as temperature changes. Solar mounting systems use clamps attached directly over the seams without penetrating the roof membrane.

B. Types and Manufacturer

Common standing seam materials:

- Steel (painted/unpainted, galvanized, Galvalume)

- Aluminum

- Zinc

- Copper (rarely)

Major seam roof manufacturers:

- Kalzip

- Zinc

- Domitec

- GBS

- Klip-Lok

There are many profiles and dimensional variances. It’s important to match the manufacturer and panel details to the appropriate seam clamp system.

II. Mounting Methods

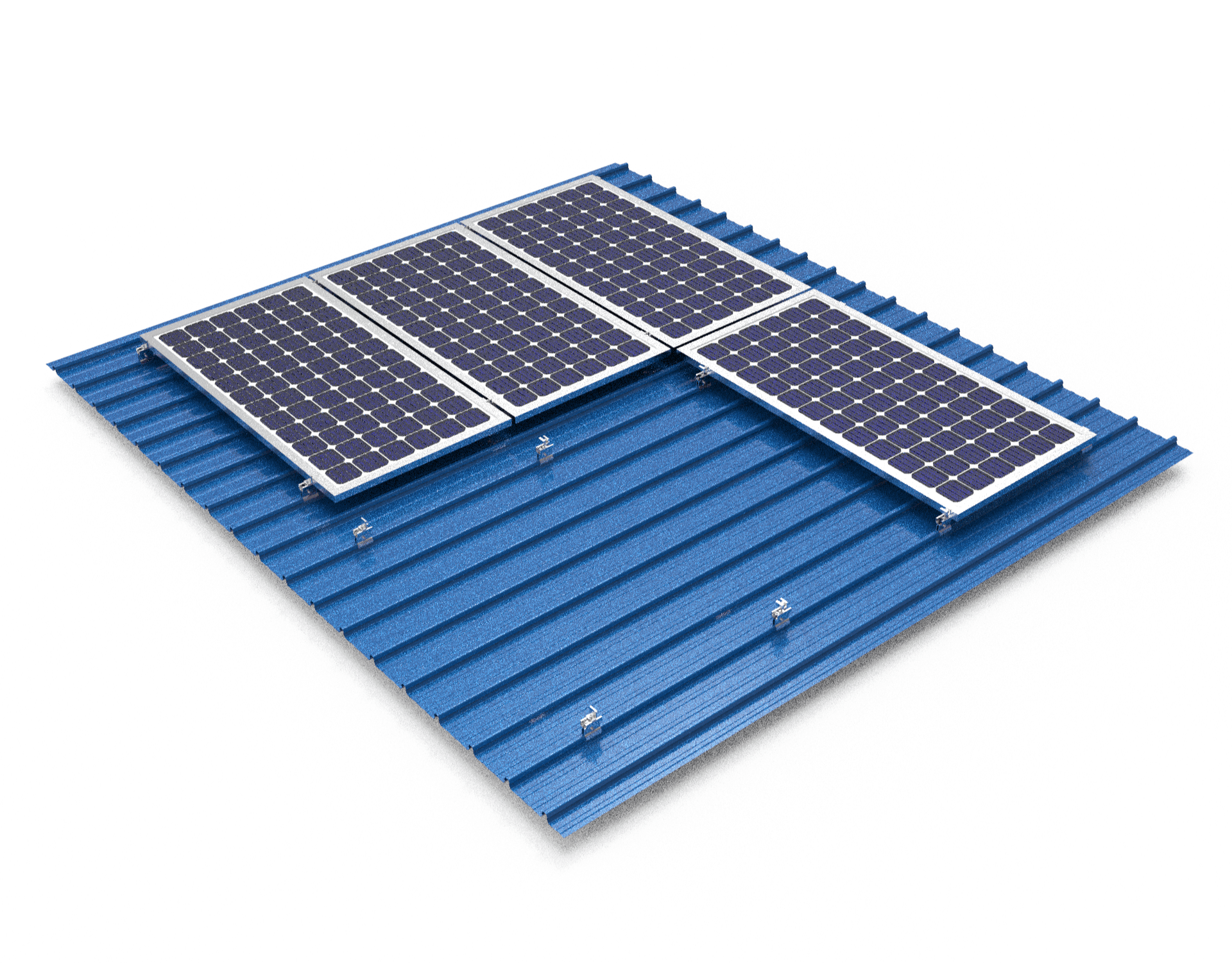

There are two main methods to mount solar PV systems onto standing seam metal roofs:

A. Seam Clamps:

Attachment hardware (rails/direct mounting)

Seam clamps

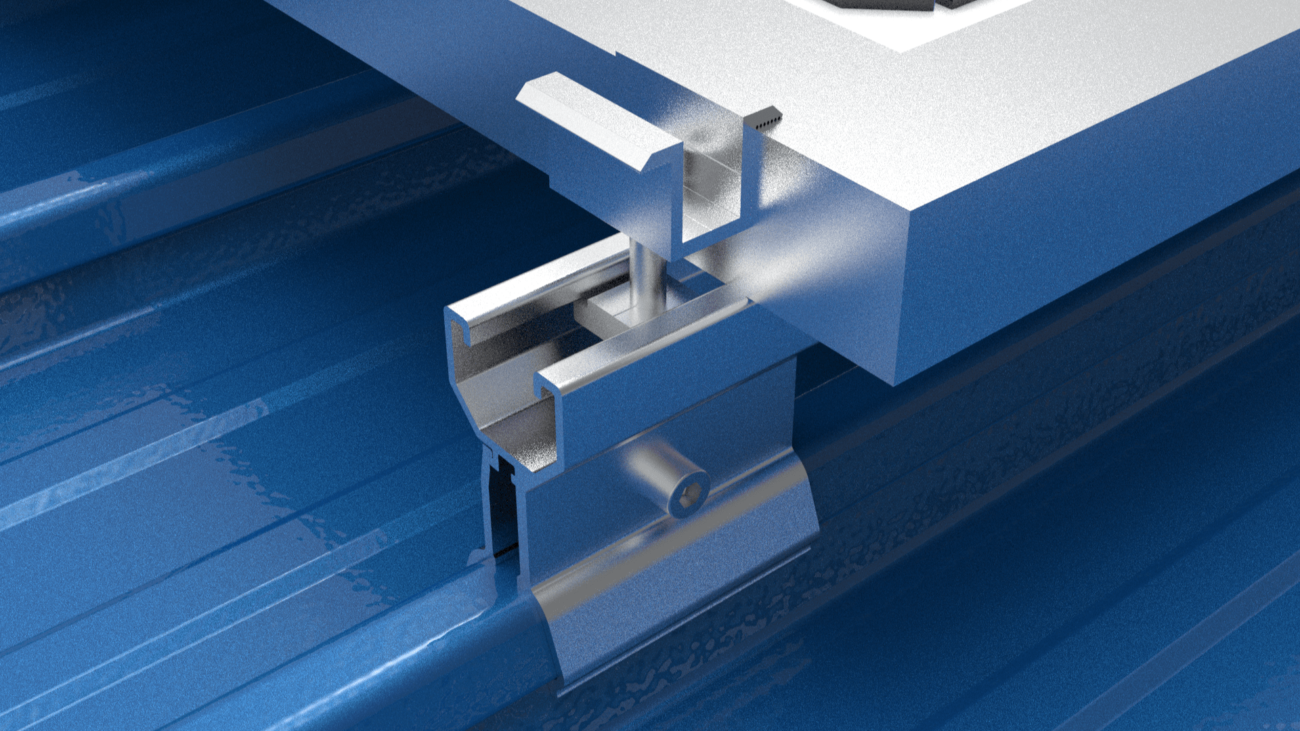

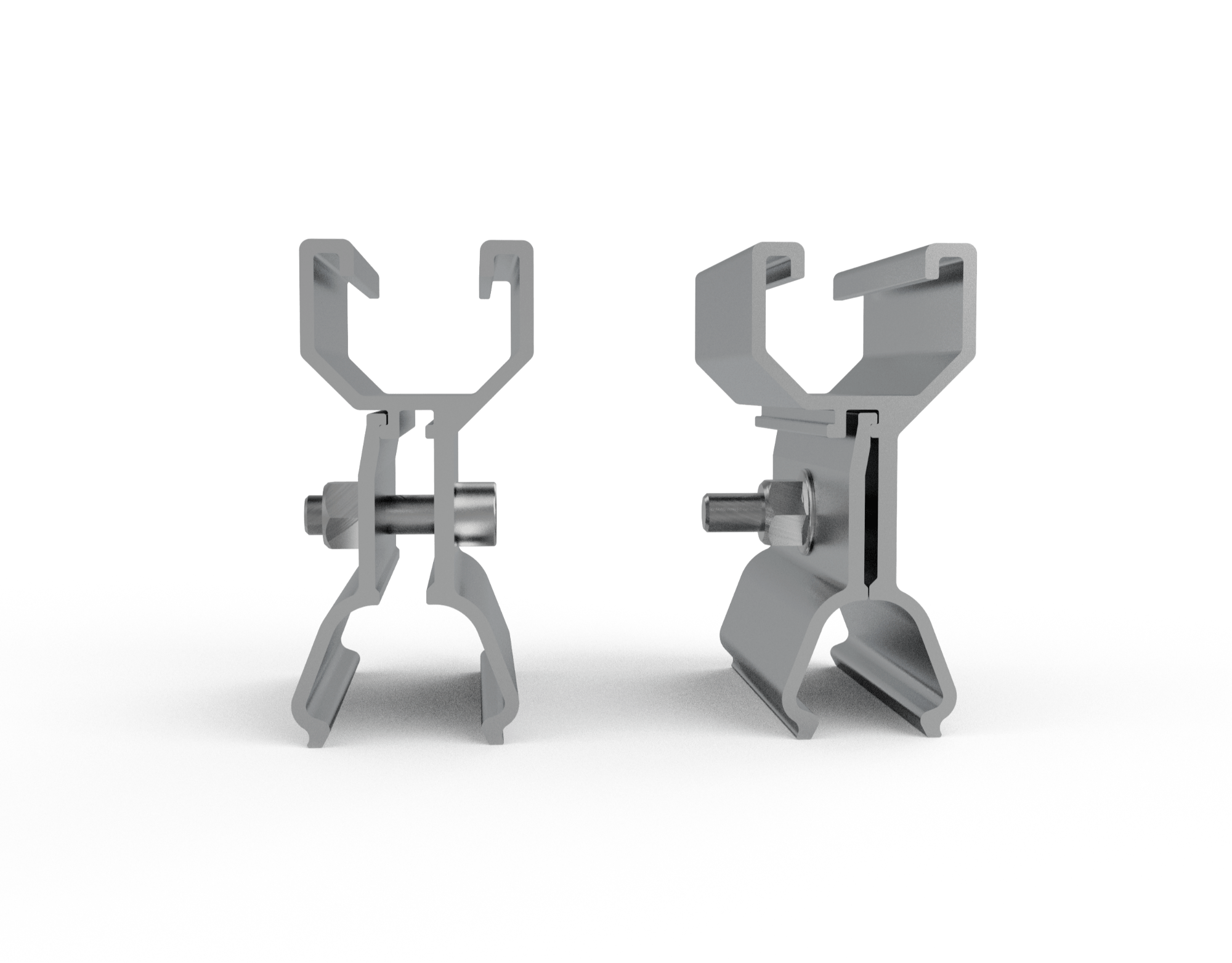

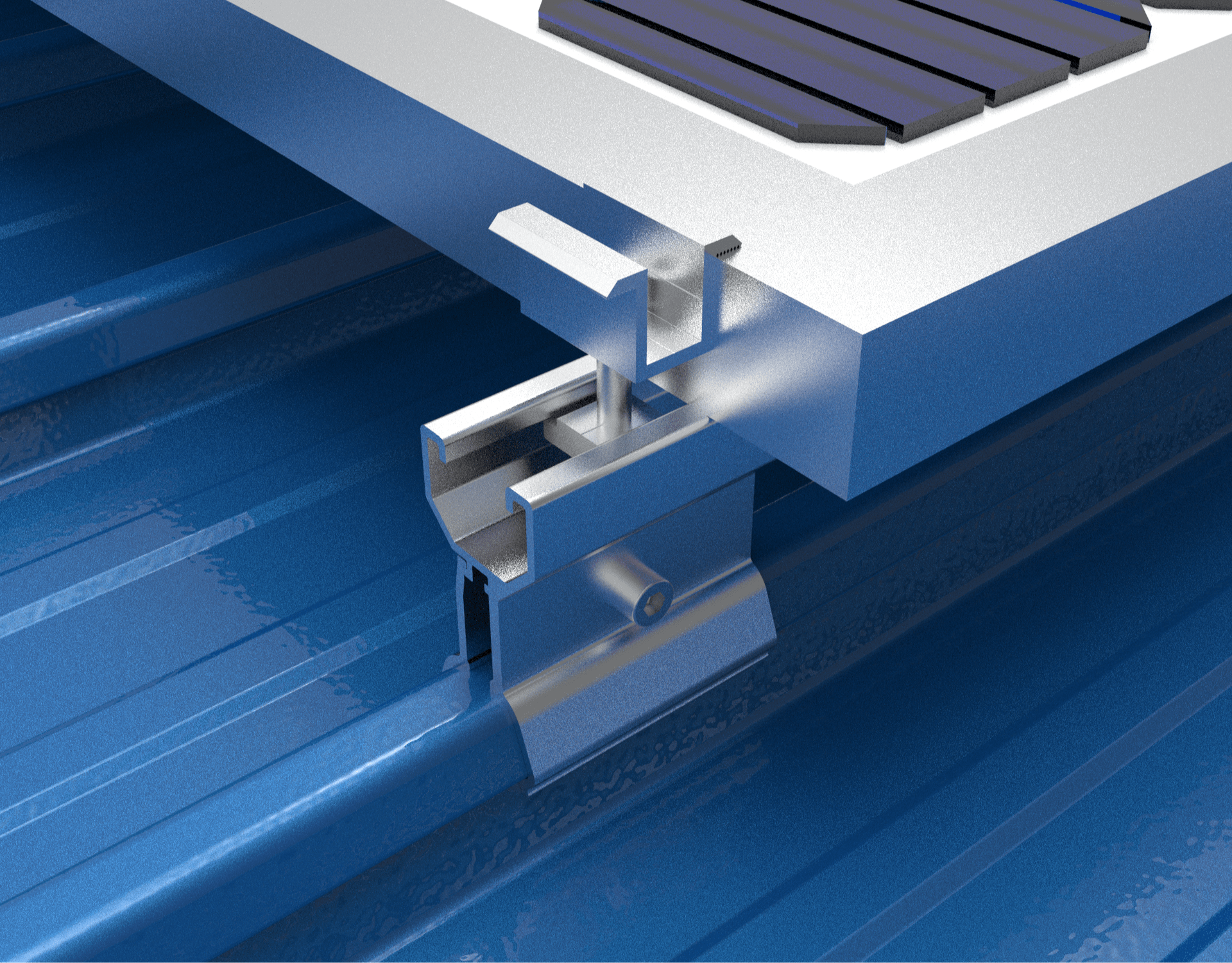

Seam clamps secure onto the raised seams mechanically, without penetrating the roof membrane. This avoids risk of leaks.

1. Securing Method:

The clamps pinch the seam using round point set screws to create a strong mechanical interlock. The clamps grab onto the full beam-like structure of the seam.

2. Location Considerations:

- Avoid mounting over panel clips allowing expansion/contraction

- Follow manufacturer guidance on seam clamp placement

- Spread clamps evenly based on load calculations

| Clamp Type | Description |

| End clamps | Anchor start/end of row |

| Mid clamps | Secure middle of panels |

| Specialty clamps | For corners or transitions |

B. Attachment Hardware:

1. Rails:

Aluminium rails bolt onto the seam clamps, spanning multiple seams. Modules mount to rails. More parts but better space utilization.

2. Direct Mounting:

Module clamps attach directly to seam clamps without rails. Fewer parts, lower cost and weight. But less adjustment flexibility.

For proper structural integrity:

- Use tested, high-quality components.

- Follow manufacturer specifications.

- Consult a structural engineer.

III. Key Considerations

There are several important factors to consider when installing solar PV systems onto standing seam metal roofs.

A. Roof Warranty and Regulations:

- Verify with the roof manufacturer that seam clamps will not void warranties

- Some manufacturers specify their own clamps to use

- Follow all local building codes and solar regulations

B. Seam Compatibility:

- The clamp must match the exact seam profile and dimensions

- Select gauges tested with specific panel profiles and materials

- Avoid mismatching metals (e.g. copper)

C. Strength Testing:

- Use published strength ratings from accredited labs

- Account for SSMR material, gauge, coating, and profile

- Recognize tests exceed panel/building strength limits

| Strength Considerations | Description |

| Clamp-to-seam | Ultimate interlock strength |

| Panel flexural | Panel bending capacity |

| Roof attachment | Pull-out resistance |

| Buckling | Roof beam buckling mode |

D. Attachment Frequency:

- Clamp strength ≠ entire system strength

- Spread attachments based on load analysis

- Avoid concentrated loading through beams

E. Costs

| System | Cost per Watt |

| Large | As Per Watt |

| Small | As Per Watt |

Consider rails vs direct mounting. Evaluate parts, shipping, labour.

IV. Additional Resources

There are industry associations and manufacturer guides available with further guidance on solar mounting best practices for standing seam metal roofs.

1. Industry Guidelines:

Metal Construction Association – Technical bulletins on:

- Seam clamp compatibility

- Fastener usage with metal panels

- Metallurgy of aluminium, galvanized steel, etc.

Solar Energy Industries Association – PV system siting and mounting considerations

2. Manufacturer Information:

A. Roofing Manufacturers:

- Review warranty info regarding attachments

- Follow manufacturer mounting guidelines

- Utilize approved clamps

B. Clamp Manufacturers:

- Published strength test results

- Seam measurements and matched clamps

- Design recommendations

C. Mounting Hardware Manufacturers:

- Follow specifications on components

- Design guidance and engineering support

| Resource Type | What They Provide |

| Roofing | Warranty info, mounting guidelines, approved clamps |

| Clamps | Test results, seam details, design guidance |

| Mounting | Specifications, engineering support |

D. Qualified Professionals:

Consult qualified solar integrators, roofers, and structural engineers trained in saddle seam roofing. Get project-specific advice accounting for all variables.

Leverage multiple resources to ensure attachments preserve roof integrity and system longevity.

V. Conclusion

In summary, standing seam metal roofs provide an ideal mounting surface for solar PV systems when proper methods are used.

A. Summary of Advantages:

Key benefits of pairing seam roofs and PV:

- Aesthetic appeal

- Enhanced energy efficiency

- Convenient structural attachment points

- Non-penetrating seam clamps avoid leaks

- Long-term durability using quality components

By following best practices for design and installation, you can achieve an integrated, high-performing system.

B. Role of Professionals:

Work with qualified experts in:

- Solar integration

- Structural engineering

- Metal roofing and attachments

Experts should:

- Accurately assess needs

- Guide appropriate mounting method selections

- Conduct project-specific calculations

- Oversee safe, high-quality execution

This ensures roof integrity, system longevity, and code compliance.

C. Ongoing Developments:

As technology improves, expect advancements in:

- Efficient panel and inverter components

- Cost-effective rail less mounting

- Robust attachment clamps

- Streamlined design tools

Stay up-to-date on innovations allowing faster, lower-cost PV mounting on seam roofs with maximum ROI.

Adhering to best practices, leveraging professional expertise, and utilizing cutting-edge mounting technology facilitates optimal solar installations on these ideal metal roofing surfaces.