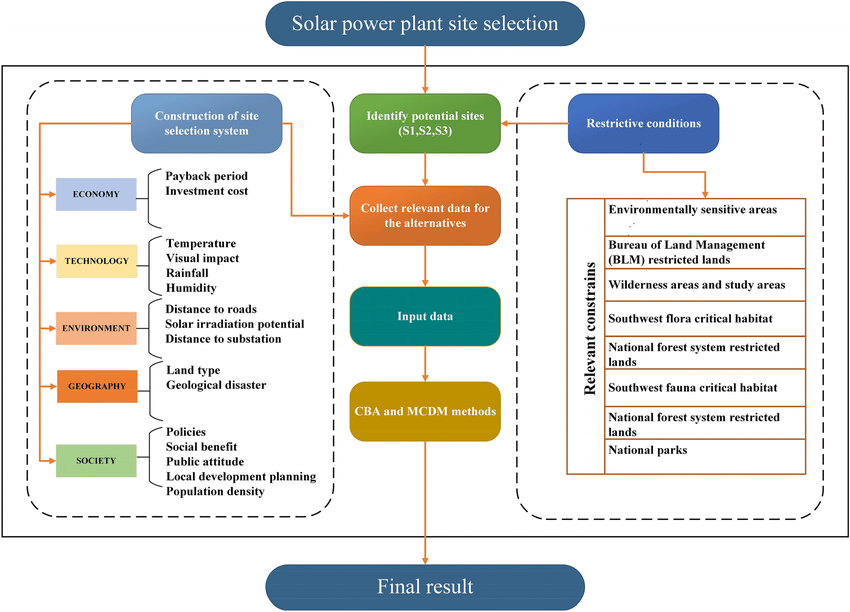

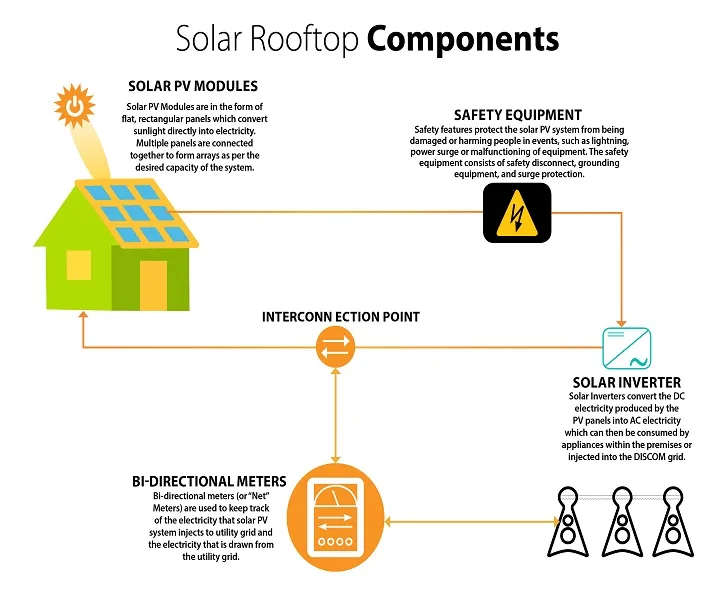

I. Introduction to Solar Panel Mounting Accessories

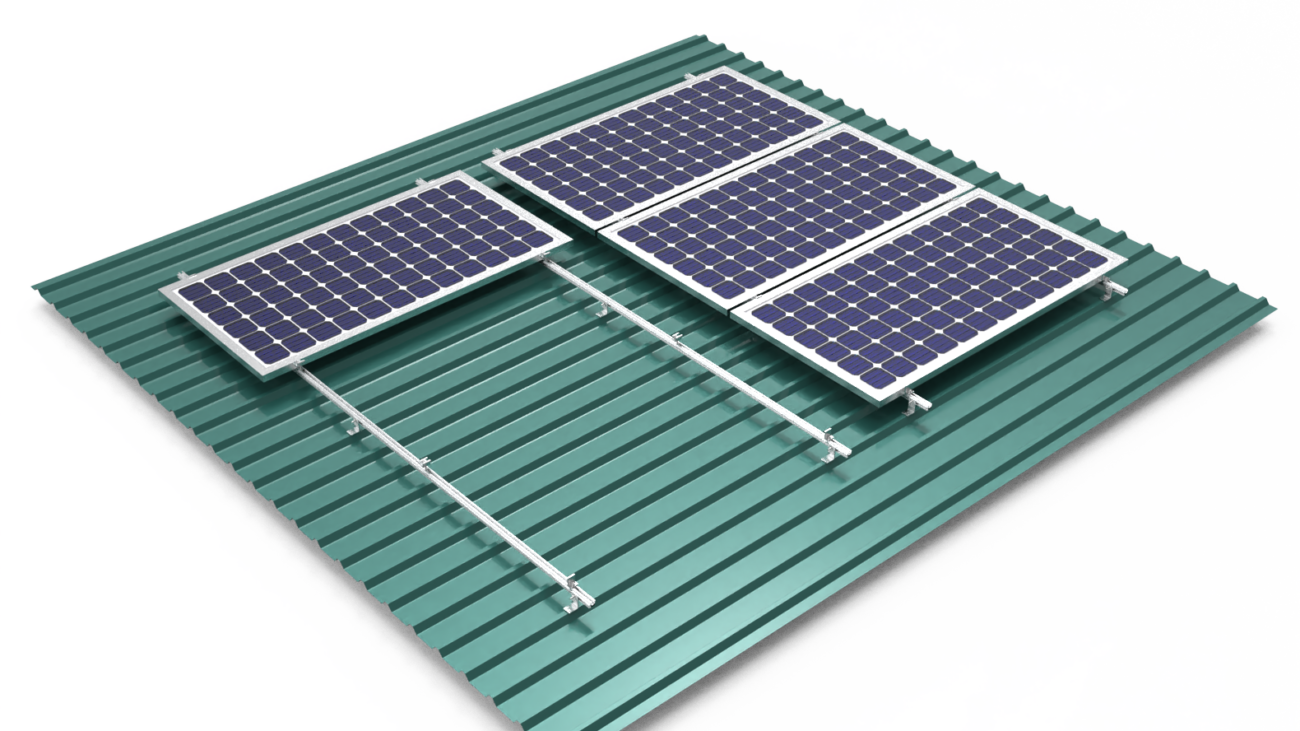

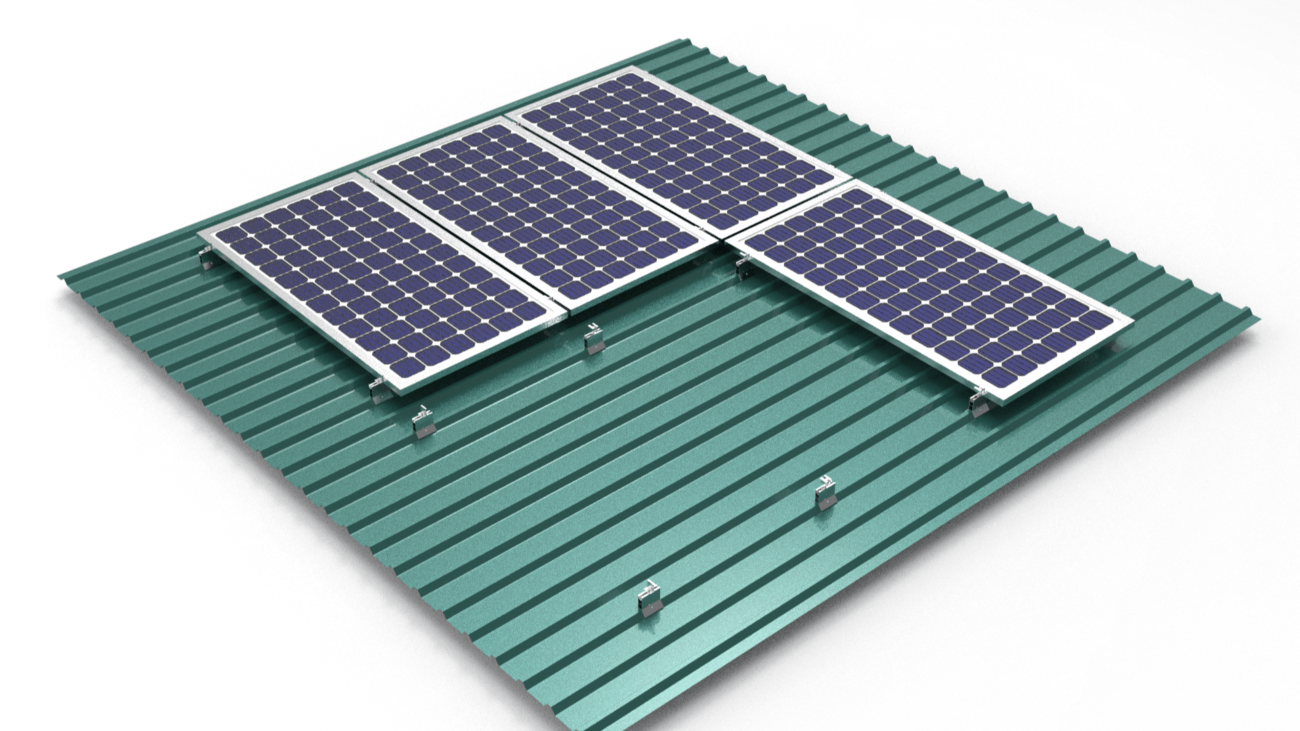

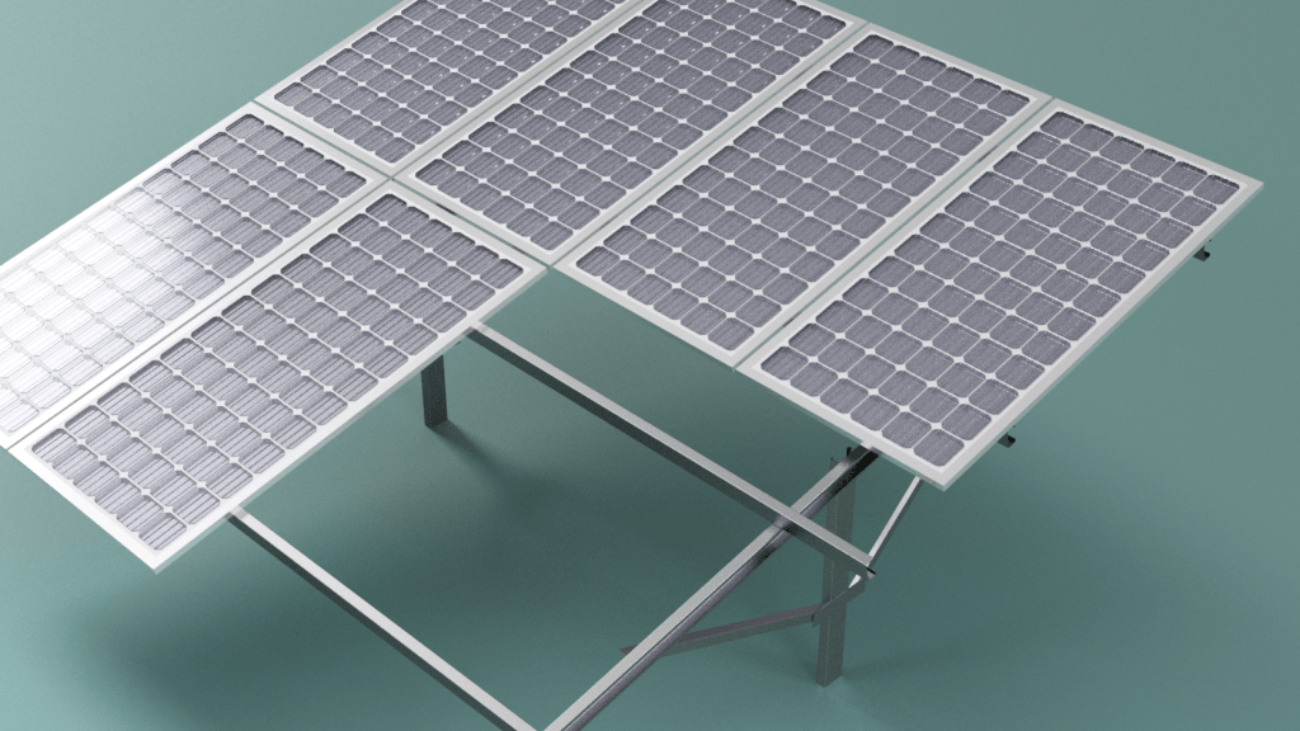

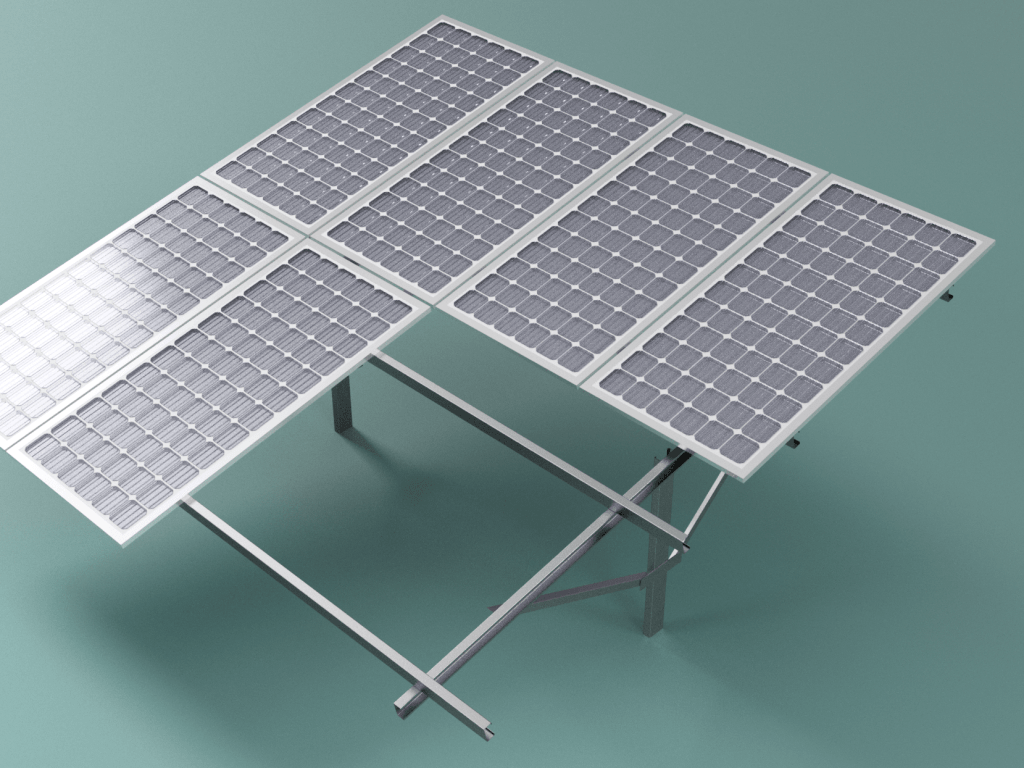

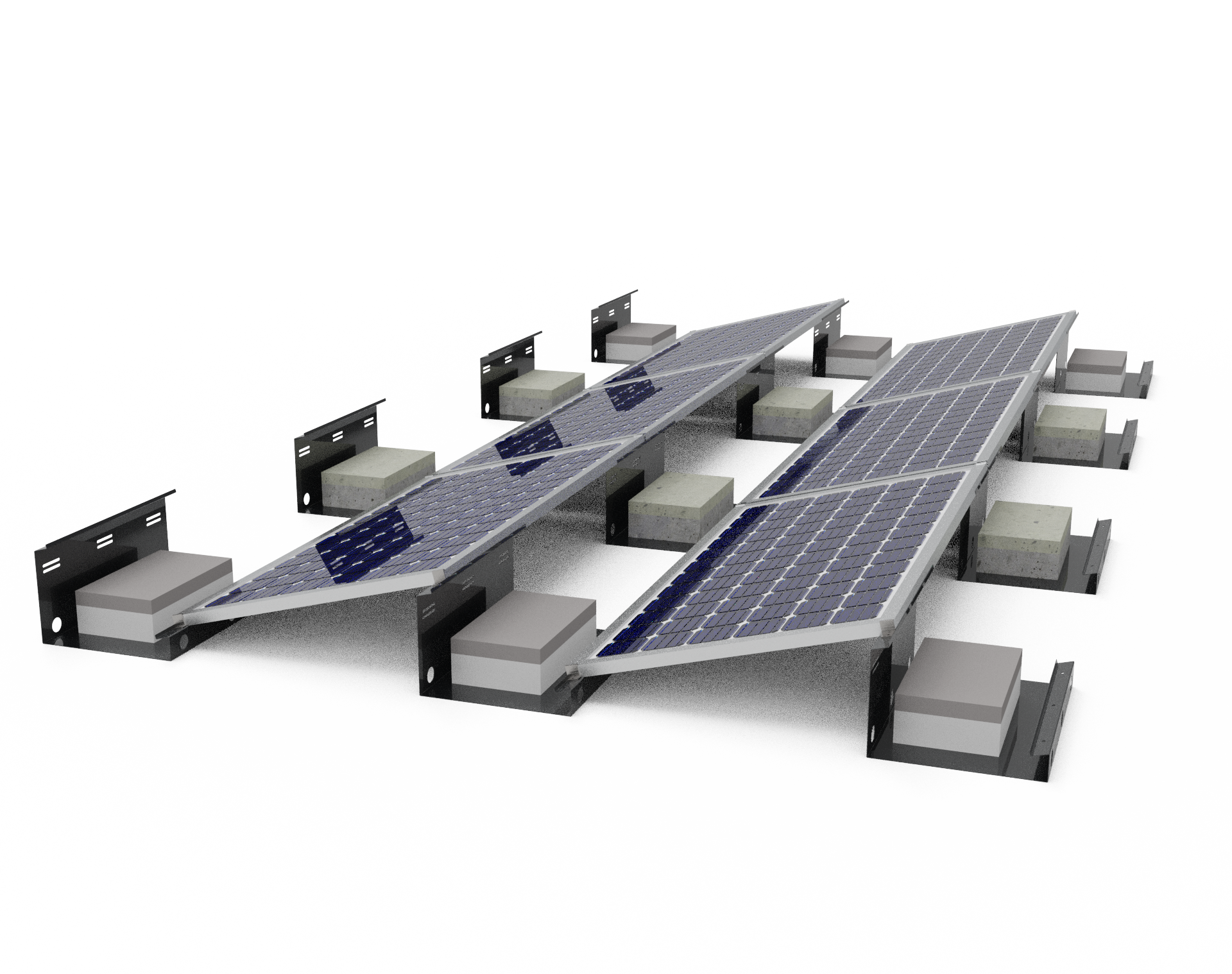

Solar panel mounting accessories are essential components of any solar panel mounting system. These accessories help securely install solar panels on rooftops, ground mounts or other surfaces.

Some key solar panel mounting accessories include:

- Solar base plate – Provides a sturdy foundation for the solar panel structure.

- Solar degree clamps – Allow adjusting the solar panel angle to optimize sunlight exposure.

- End Z clamps – Attach solar panels securely to the mounting rails.

- Middle U clamps – Hold solar panels together on mounting rails for stability.

- Power snaps – Anti-theft clips to prevent solar panel theft.

- Nuts and bolts – Fasten all components of the solar structure together.

- Fastener chemicals – Bond mounting bolts to the installation surface for strength.

| Accessory | Purpose |

| Solar base plate | Foundation |

| Solar degree clamp | Angle adjustment |

| End Z clamp | Panel attachment |

| Middle U clamp | Stability |

| Power snap | Security |

| Nut/Bolt | Structure |

| Fastener chemical | Strength |

These solar panel mounting accessories are made from durable materials like steel and aluminum. They can withstand tough outdoor conditions for long periods.

Using the right mounting accessories improves the safety, performance and lifespan of any solar panel installation. They provide the structural integrity needed to keep solar panels fixed securely under different wind, weather and environmental conditions.

Investing in good quality mounting accessories like spring nut-bolts, SS Allen bolts and structural fastener chemicals ensures your solar power system will function optimally for many years.

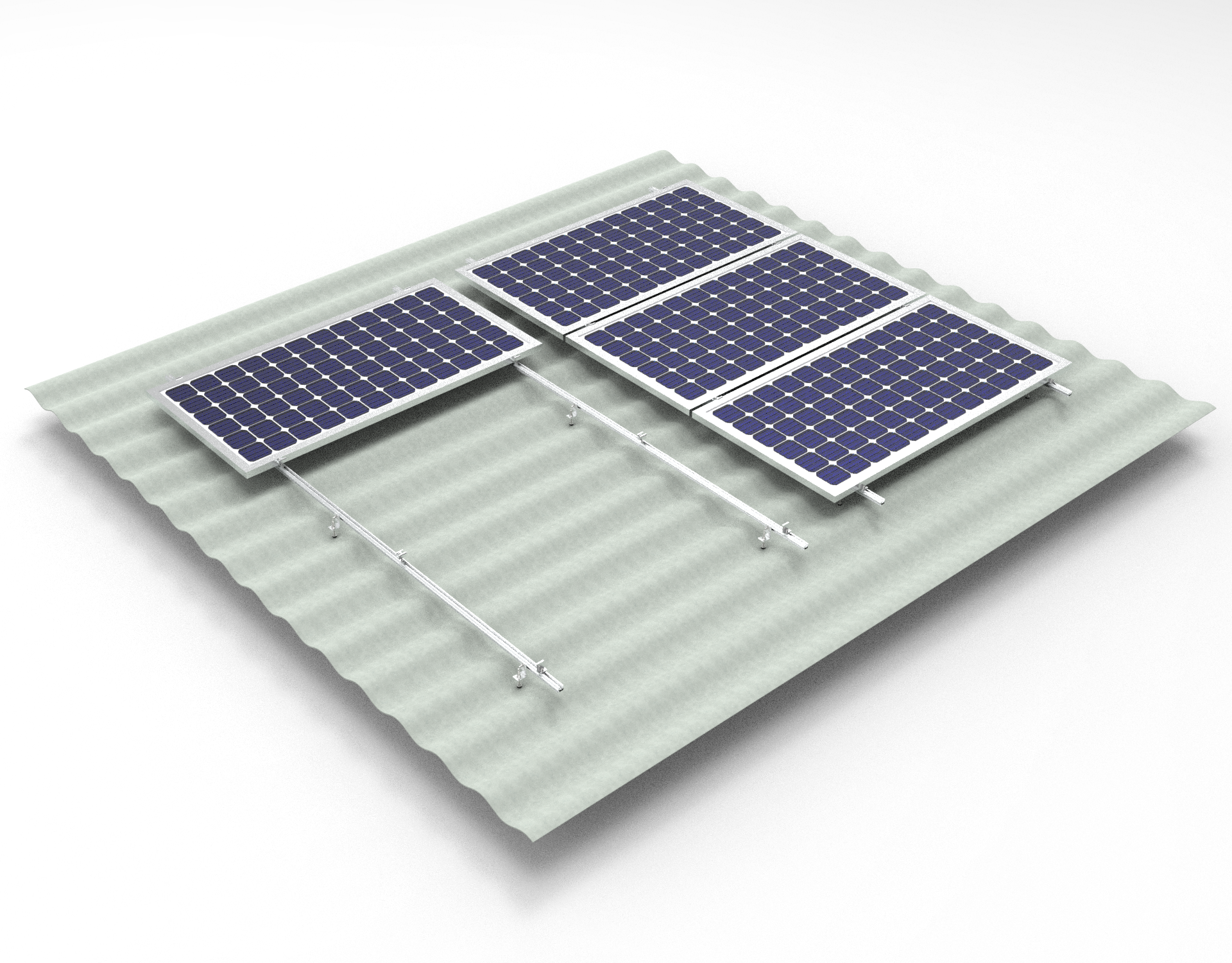

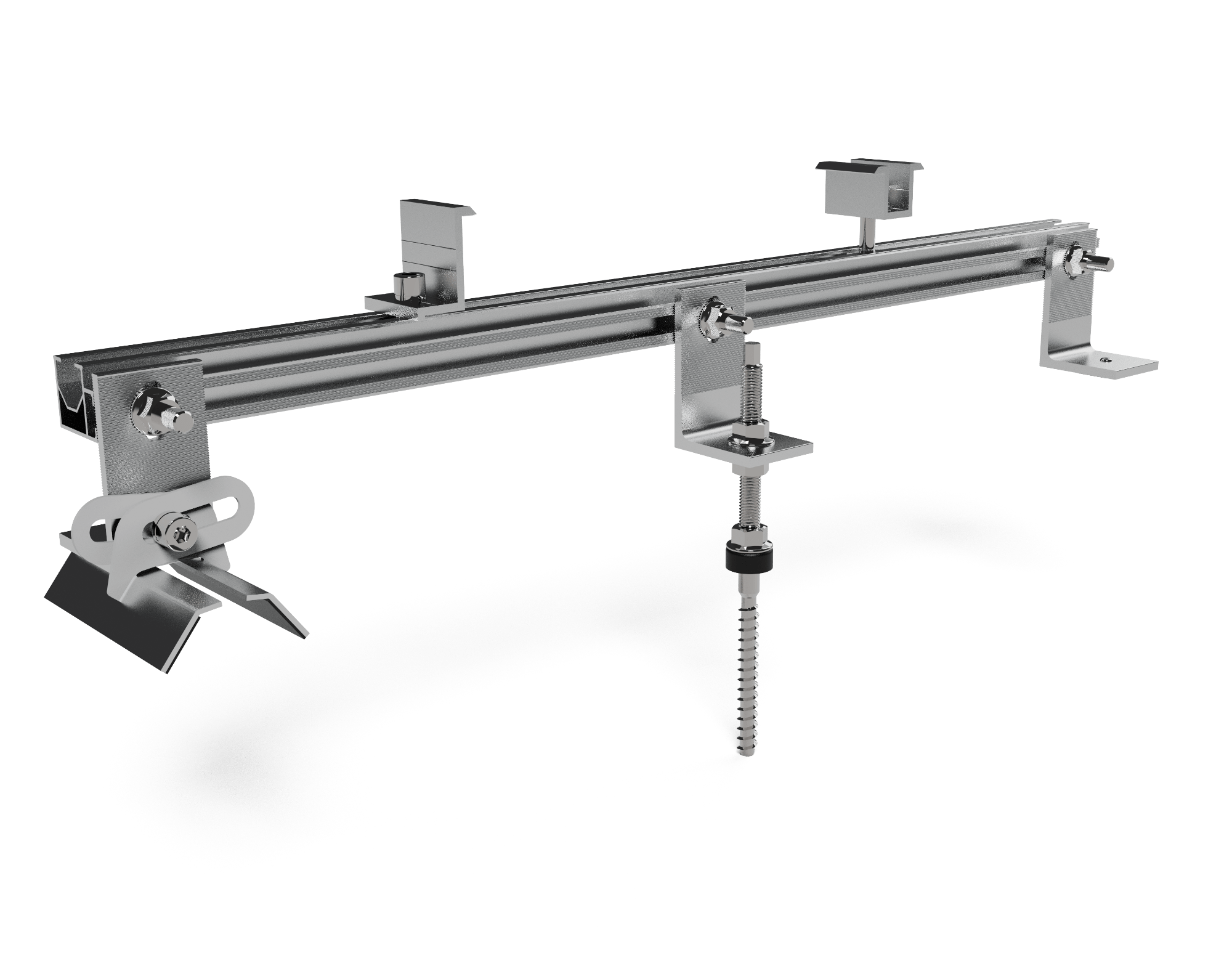

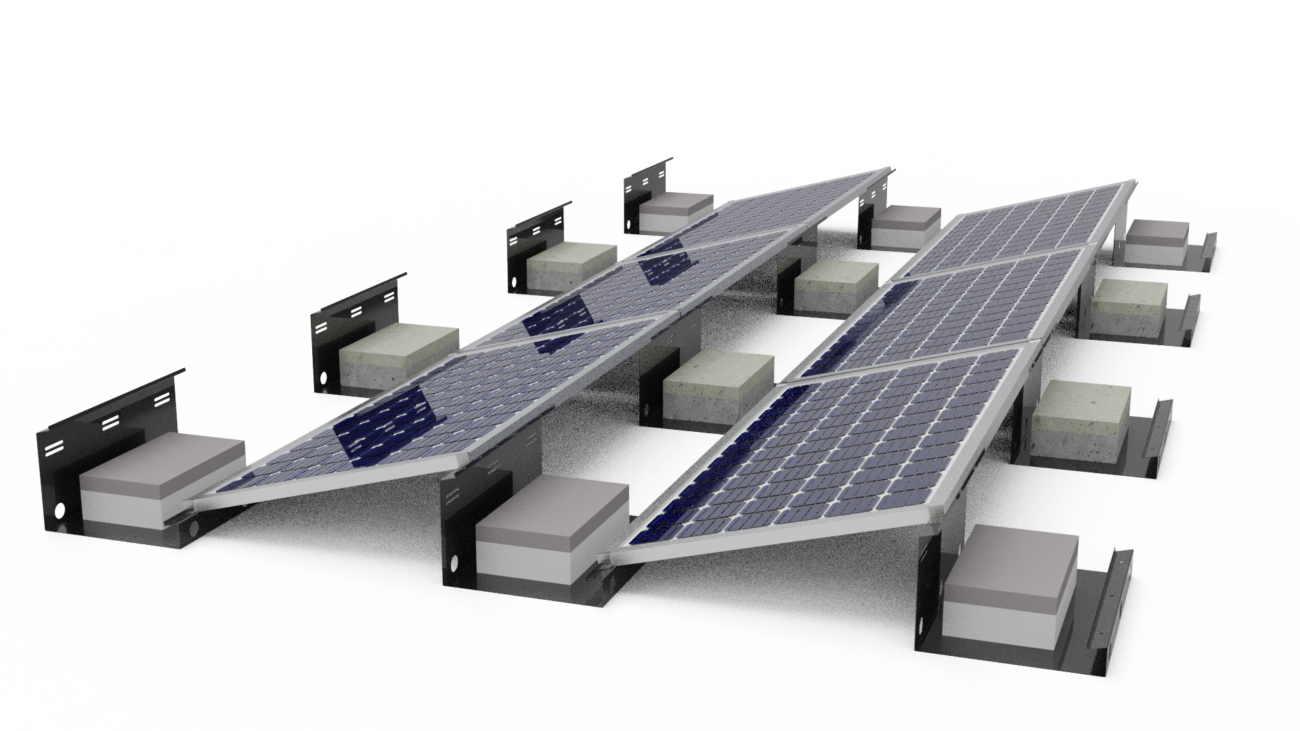

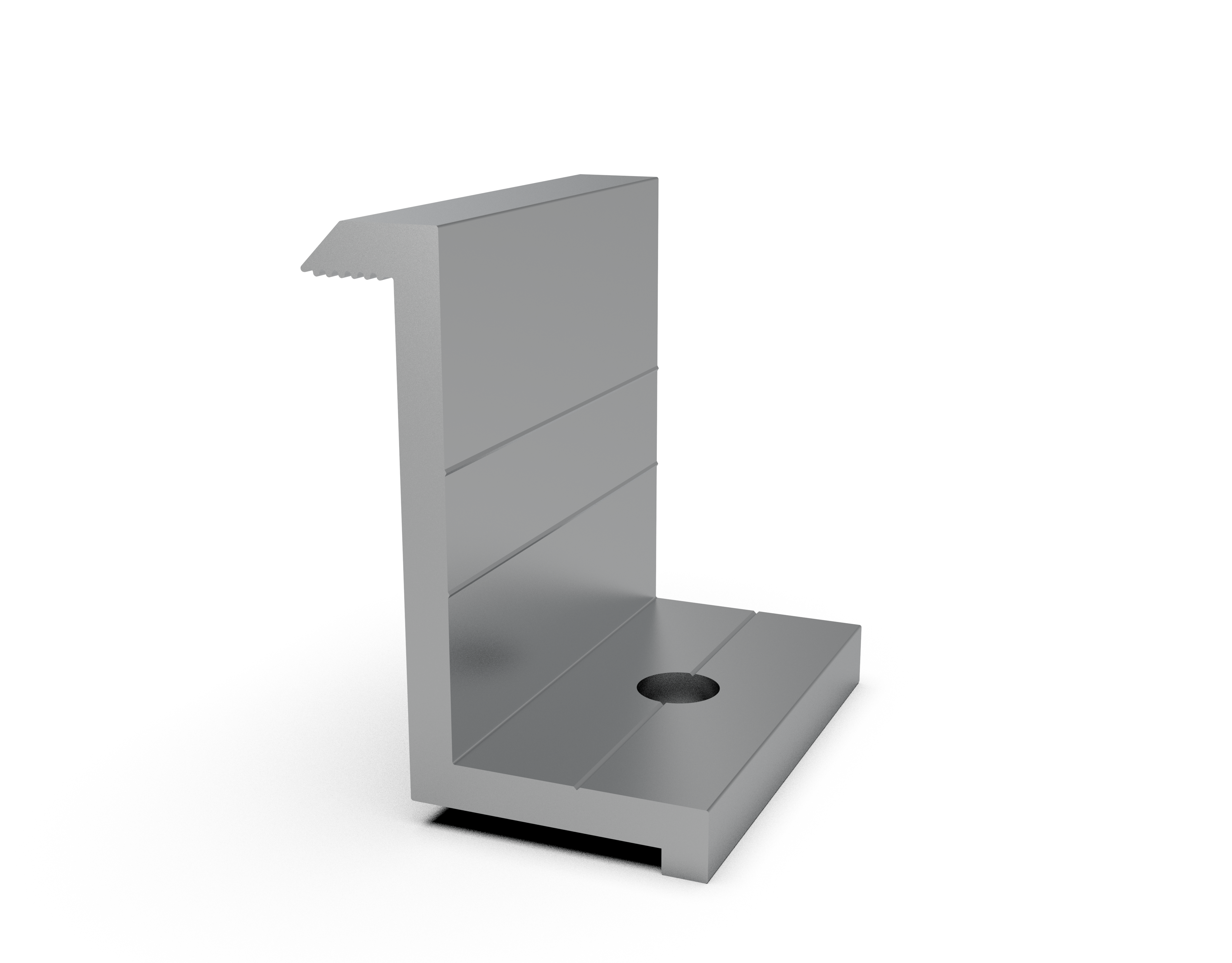

II. Solar Base Plate for Foundation

The solar base plate provides a sturdy foundation for the entire solar panel mounting structure. It is installed directly on the roof, ground or any other mounting surface.

The base plate bears the weight of solar panels, racks and other components. It must be made of durable materials like:

Base plates are available in different sizes like:

- 41mm x 41mm

- 80mm x 40mm

Larger solar panel installations require bigger base plates for greater load bearing capacity.

The key functions of a solar base plate are:

- Anchor the mounting structure securely to the installation surface.

- Resist corrosion and environmental damage.

- Support the weight of solar panels, racks, wires etc.

- Withstand high winds without failing.

A proper foundation is crucial for safety and performance of the solar power system. High quality base plates ensure:

- Long term mounting structure stability.

- Optimized energy output.

- Reduced risk of collapse or damage.

Invest in sturdy and appropriately sized solar base plates for your installation. Proper selection and installation of base plates will maximize the lifespan of your solar panel mounting system.

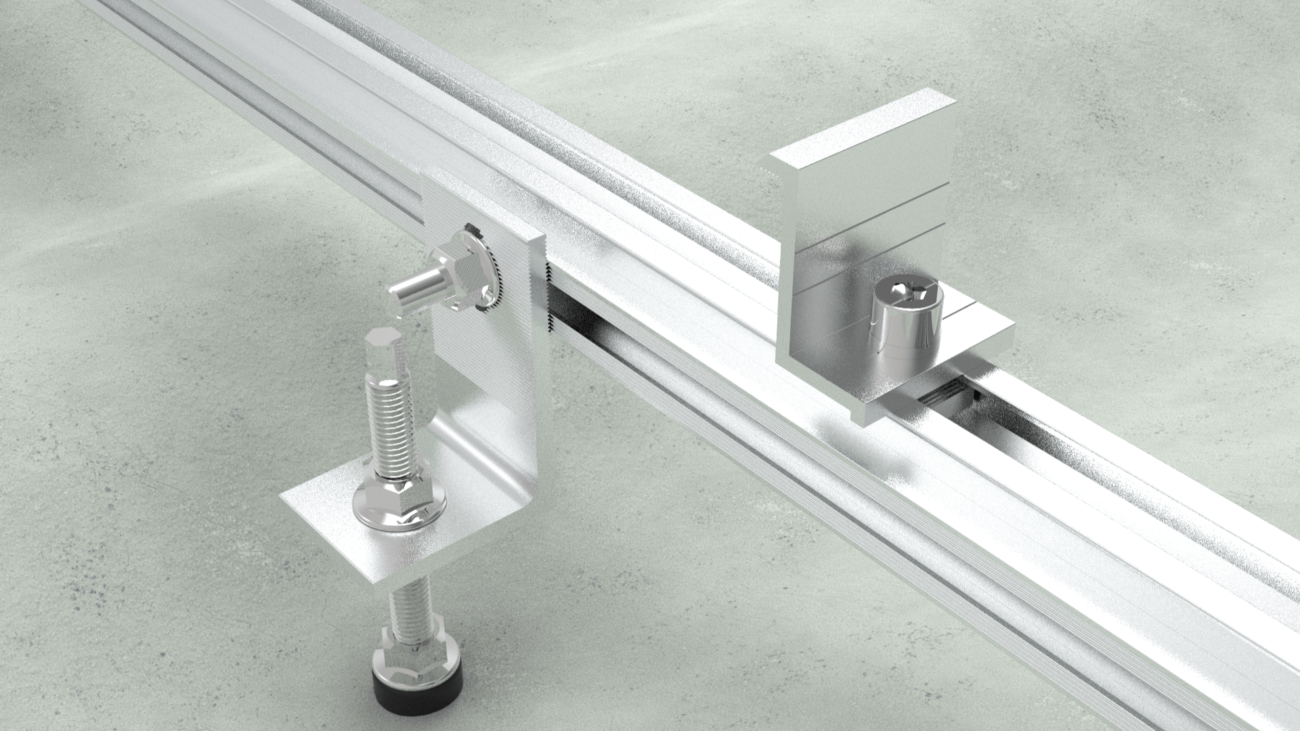

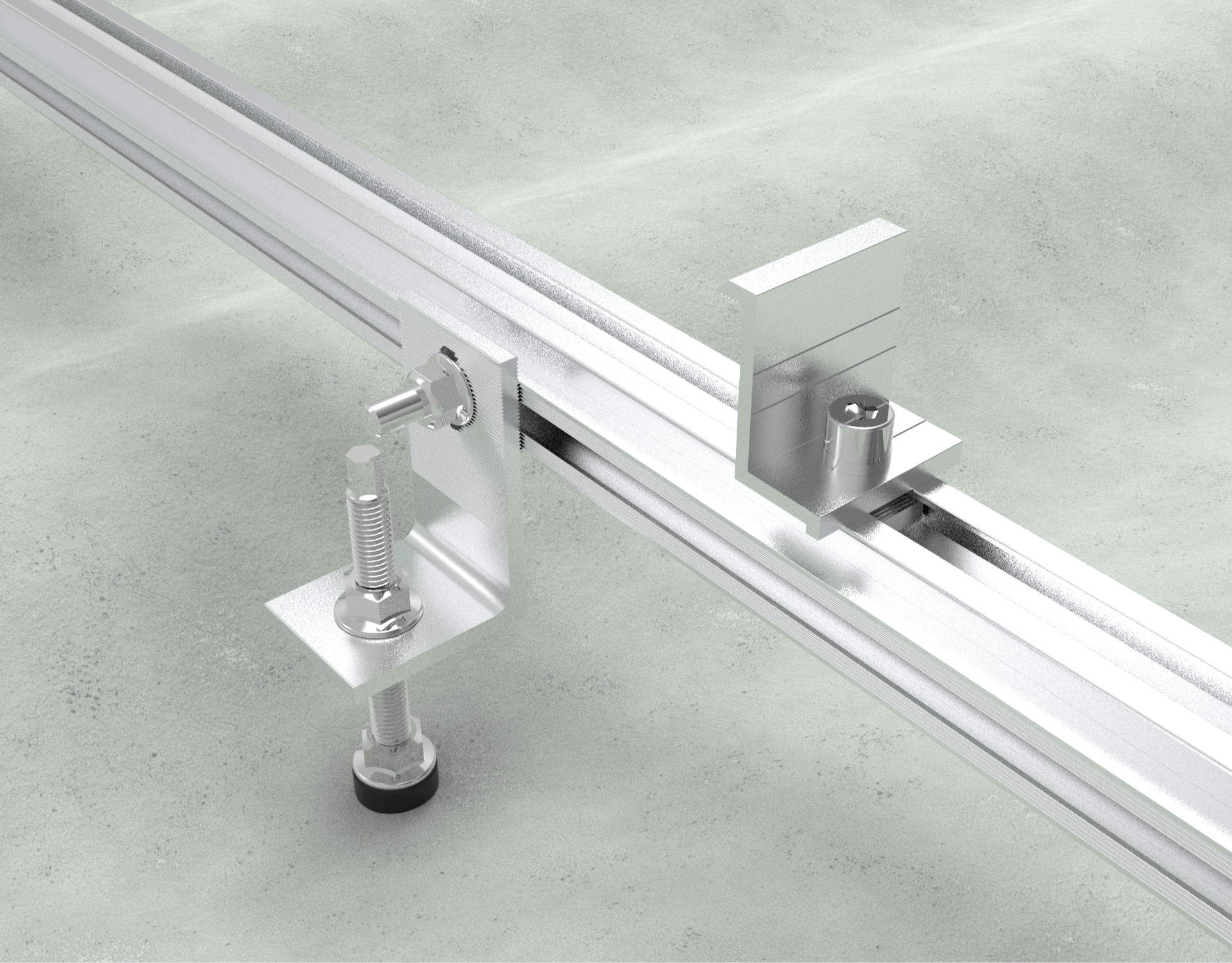

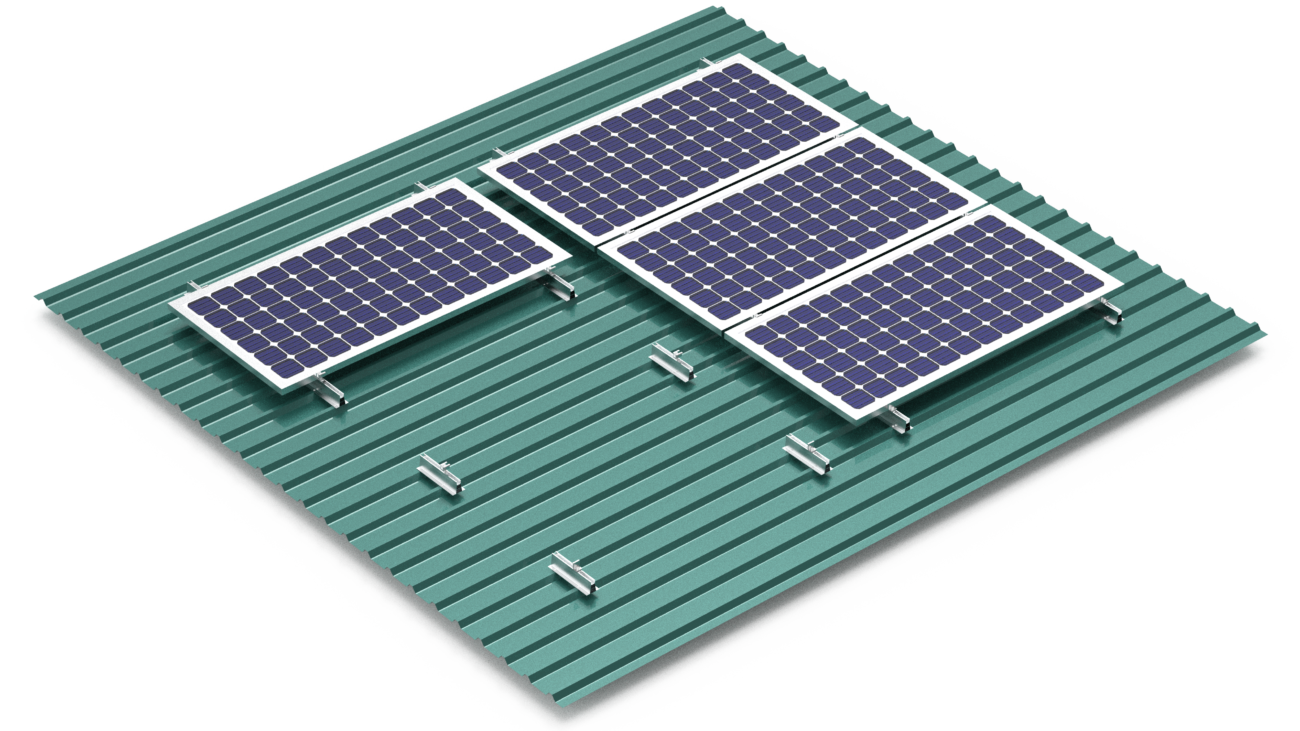

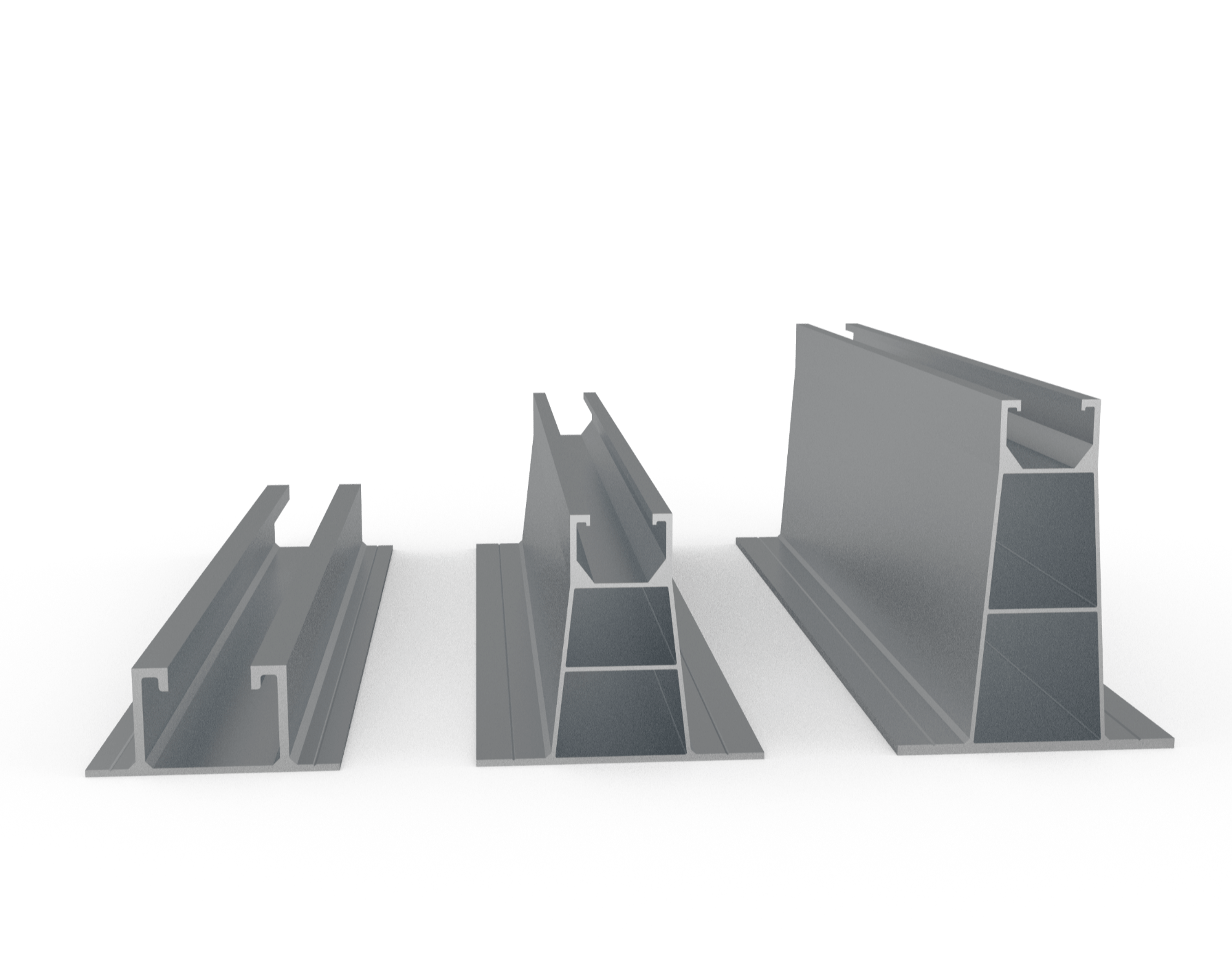

III. Solar Degree Clamps for Angle Adjustment

Solar degree clamps allow for seasonal tilt angle adjustment of the solar panels to optimize energy production.

These clamps are installed between the solar panel frames and the mounting rails. They have adjustable knobs that can tilt the panels at different angles.

Degree clamps are available in different sizes like:

- 41mm x 41mm

- 80mm x 40mm

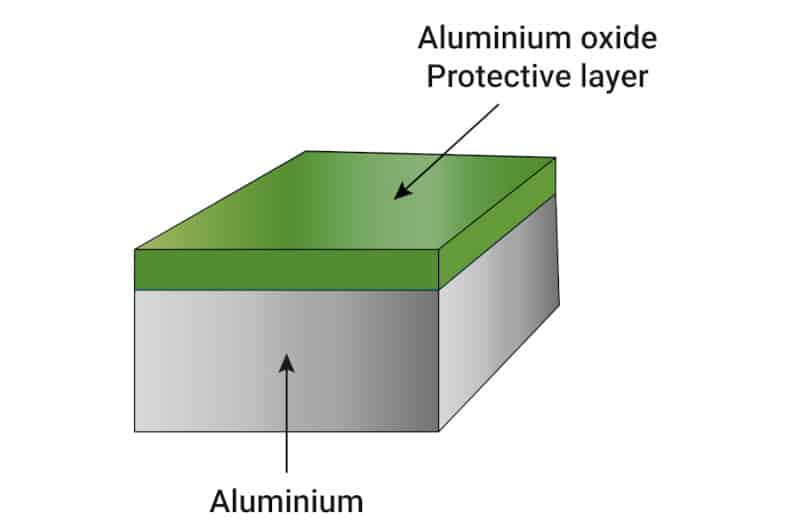

- High quality solar degree clamps are made of materials like:

- Anodized aluminum

- Stainless steel

Key features of degree clamps include:

- Adjustability range of at least 45 degrees tilt.

- Corrosion resistant construction.

- Easy to install knob bolts.

- Compatibility with panel frame sizes.

Proper tilt angle as per sun’s position ensures:

- Maximum sunlight exposure on the solar panels throughout the year.

- Optimized power output.

- Enhanced return on investment.

Solar degree clamps must be robust enough to hold the panels steadily at the right angles. Investing in properly sized, good quality clamps will maximize energy production from your photovoltaic system.

Annual seasonal adjustment of panel angles using degree clamps improves solar electricity generation and economic viability of the installation.

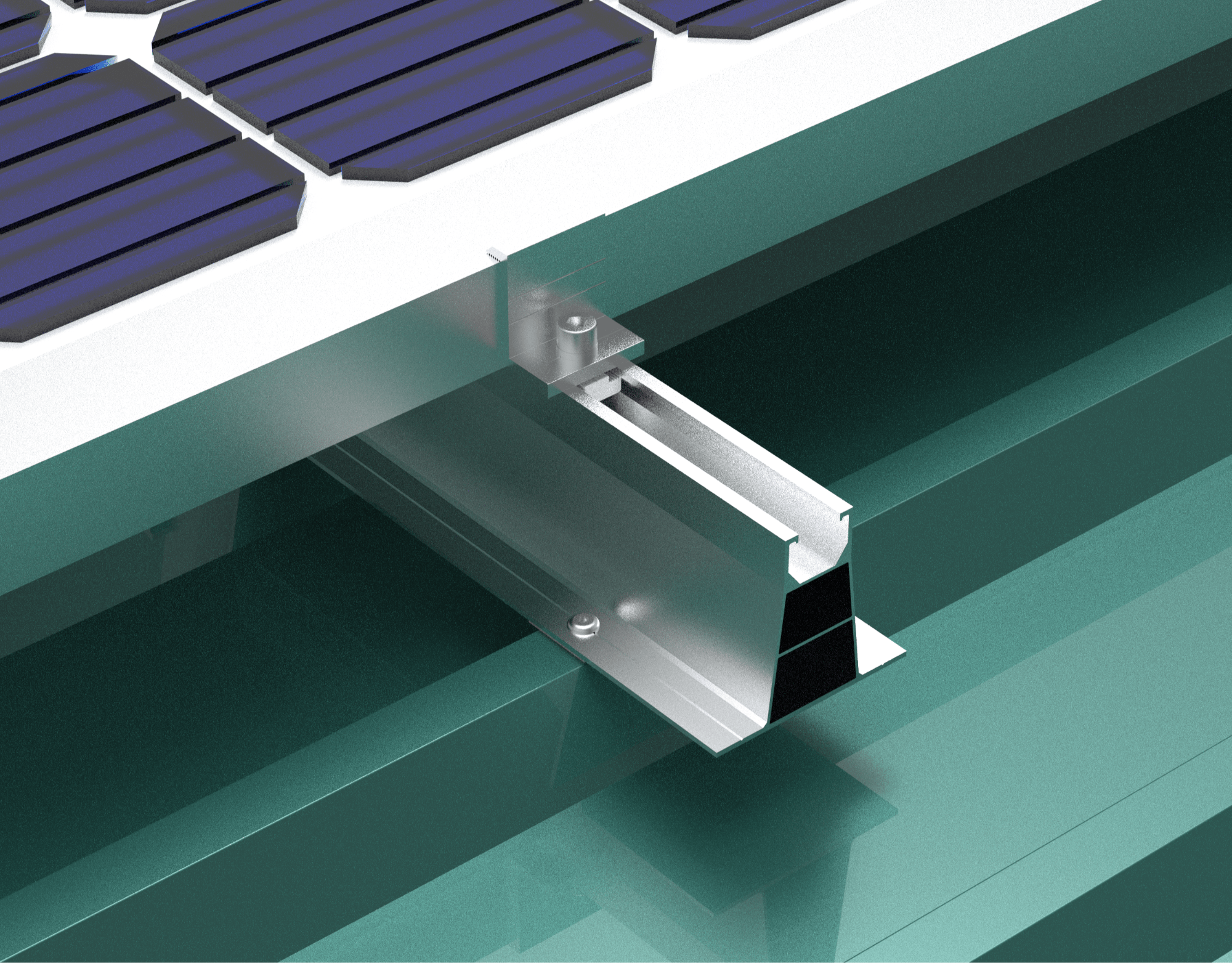

IV. End Z Clamps to Attach Panels

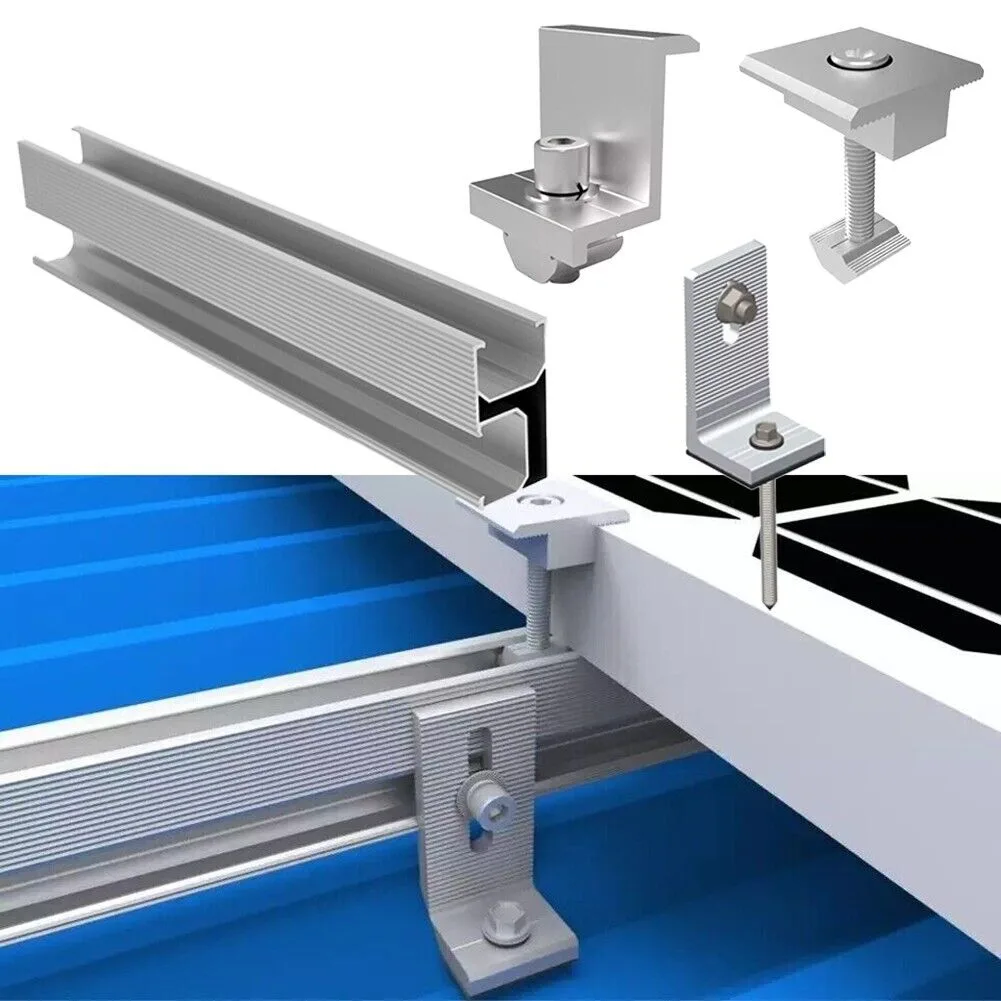

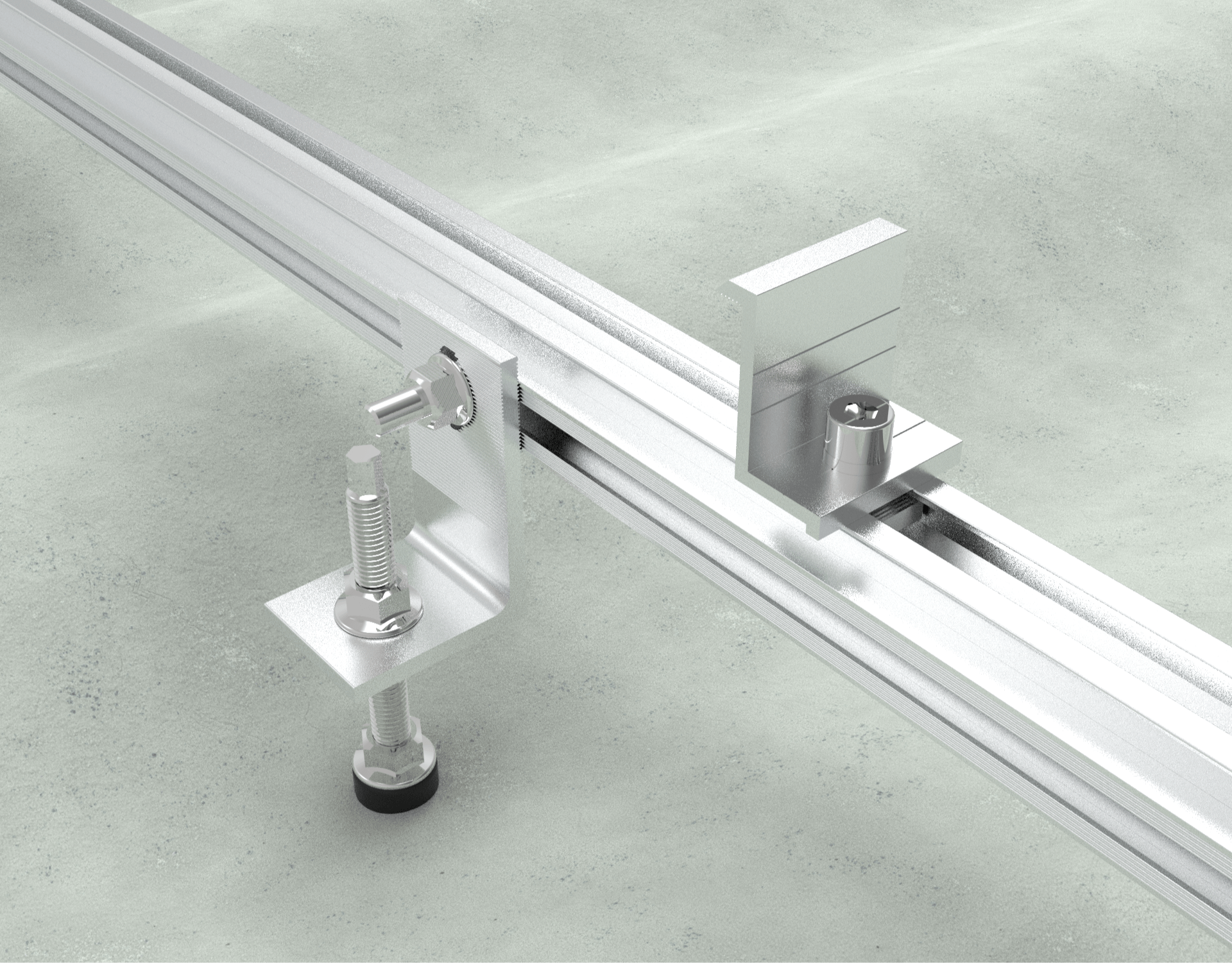

End Z clamps are used to securely attach the solar panels to the mounting rails of the structure.

These clamps have a unique Z-shape design that tightly grips the edge of the solar panel frame on one side and the mounting rail on the other.

Key features of high quality end Z clamps include:

- Sturdy aluminum or galvanized steel construction.

- Weather resistant build.

- Pre-drilled holes for easy installation.

- Long lasting finish to prevent corrosion.

End clamps are available in various sizes to match different solar panel frame dimensions.

Benefits of using end Z clamps:

- Provide very secure attachment of panels without gaps or loosening.

- Allow for quick and easy panel installation.

- Suitable for long term outdoor use.

- Reusable if panels need rearranged.

Proper panel attachment is crucial for:

- Optimized solar energy production.

- Withstanding wind, rain and other weather events.

- Preventing panel theft.

- Ensuring long term safety and function.

Invest in good quality end Z clamps designed specifically for your solar panels. Correct installation using the right clamps will maximize the stability and lifespan of your photovoltaic system.

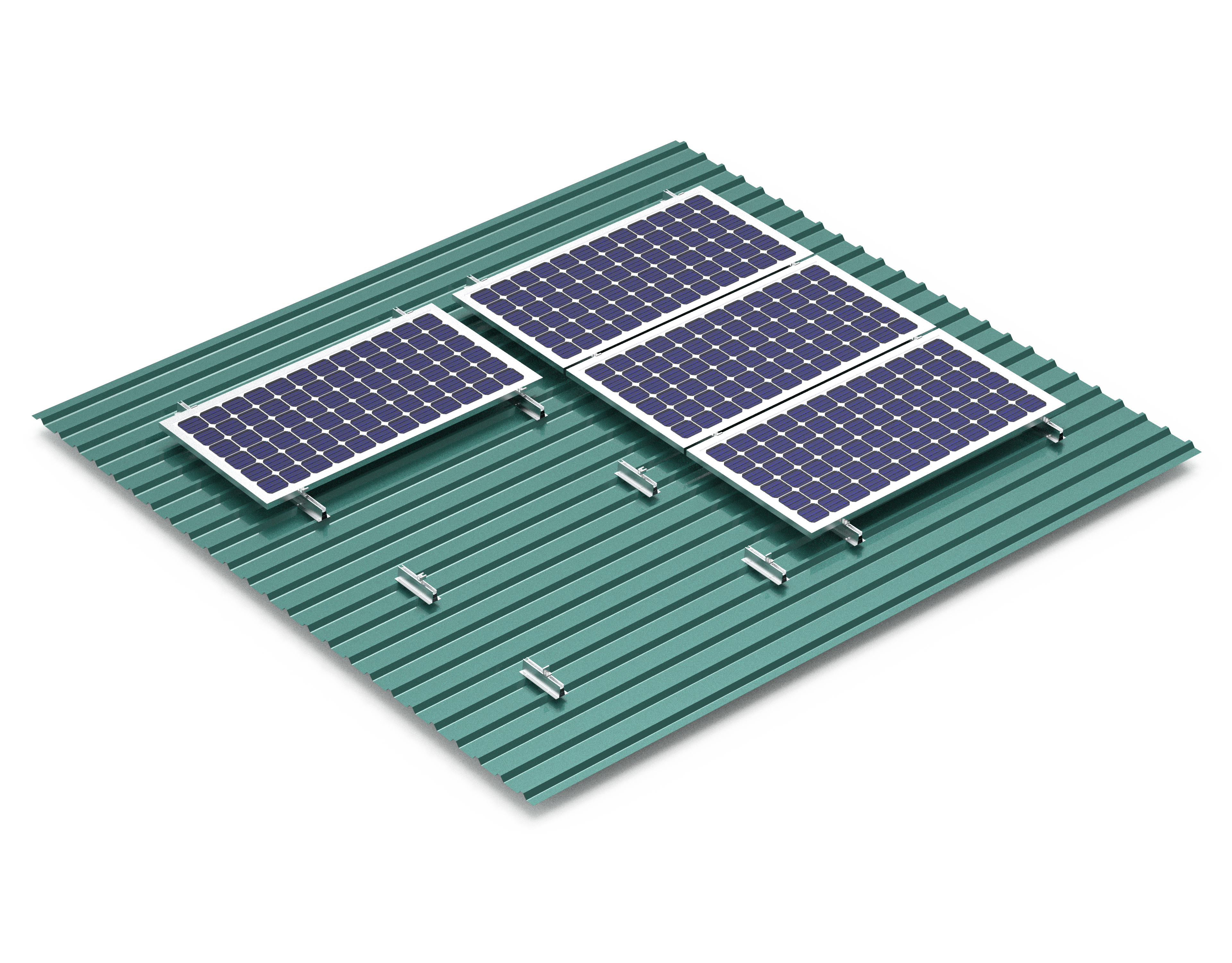

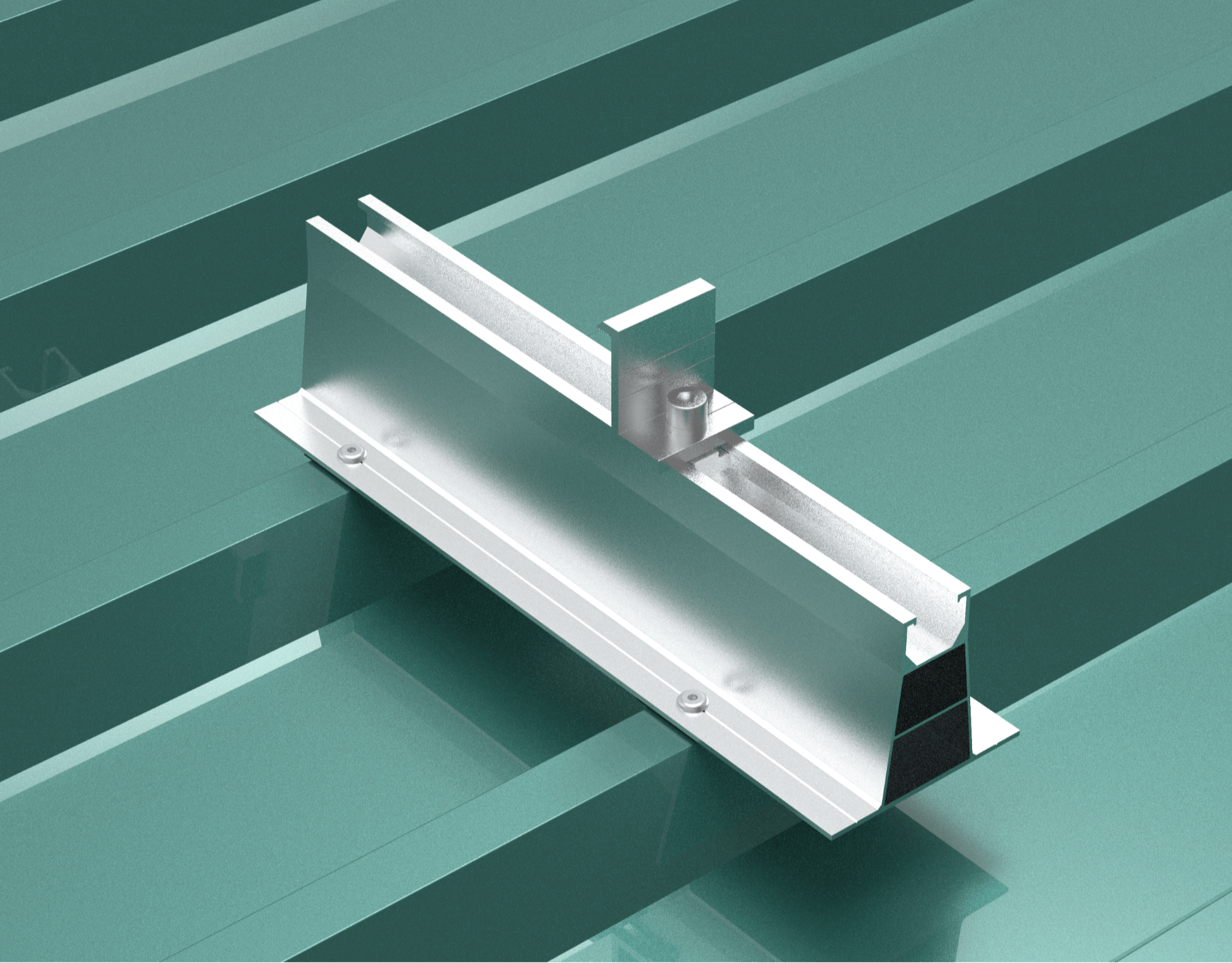

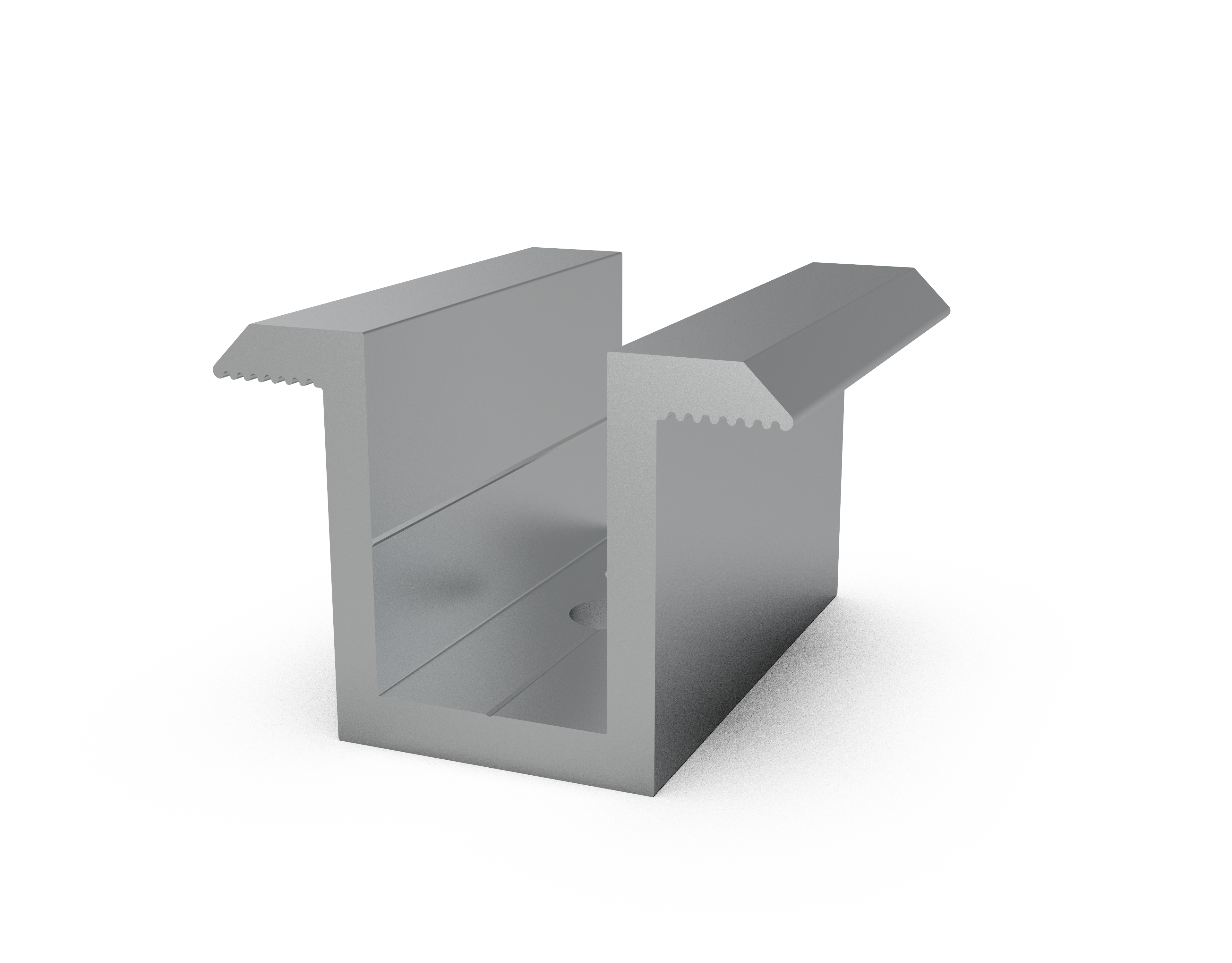

V. Middle U Clamps

Middle U clamps are installed between two adjacent solar panels on the mounting rail for optimum stability.

These U clamps have a curved, rounded shape that securely grips the edges of two panels equally.

Key features of high quality middle U clamps are:

- Durable aluminum or galvanized steel construction.

- Corrosion resistant finish.

- Available in various sizes to fit panel frames.

- Pre-drilled holes for quick installation.

Benefits of using middle U clamps:

- Prevent panels from sliding down or drifting apart.

- Provide excellent structural support.

- Suitable for all types of solar panel mounting structures.

- Reusable if panel positions need adjusted.

Proper stability of the solar panels ensures:

- Optimized energy production over time.

- Ability to withstand weather events like storms, snow etc.

- Long term safety and function of the system.

- Reduced maintenance costs.

Invest in appropriately sized, high quality middle U clamps designed for your specific solar panels. Correct installation of these clamps will maximize the structural integrity and lifespan of your photovoltaic system.

Key features of power snaps:

- Made of durable UV-resistant plastic.

- Available in different sizes to fit rail dimensions.

- Require no tools for installation.

- Reusable as needed.

Benefits of power snaps:

- Deters potential solar panel theft.

- Provides extra peace of mind and security.

- Suitable for all types of panel mounting structures.

- Quick and easy to install.

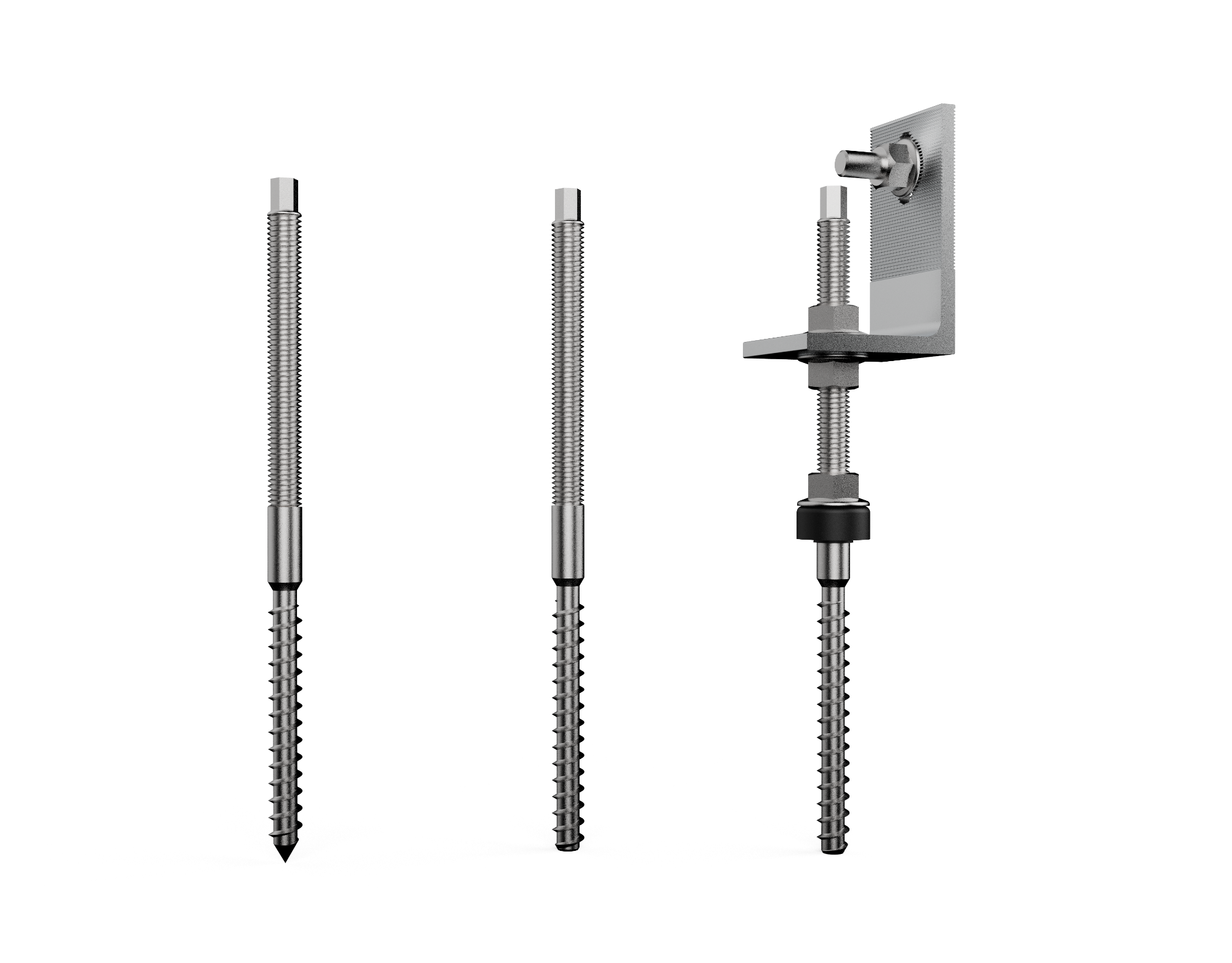

VII. Nuts and Bolts for Structure

Nuts and bolts are used extensively in solar panel mounting to assemble the structural framework.

Common types include:

- Spring nuts – Allow easy insert of bolts into drilled holes.

- SS Allen bolts – Tighten panels and components securely.

- Stud bolts – Attach items like junction boxes.

Benefits of using the right nuts and bolts:

- Strong assembly of the entire mounting structure.

- Ability to withstand weather elements like rain, wind.

- Long term integrity and stability.

- Reusability during the maintenance.

High quality hardware is essential for:

- Optimized energy production over decades.

- Reduced risk of structural failures.

- Lower maintenance time and costs.

Choosing appropriately sized nuts and bolts made of durable materials ensures a sound framework for your solar panels. Periodic inspection and proper re-tightening preserves the stability and lifespan of the installation. Investing in good quality mounting hardware is vital for a robust and long-lasting solar power system.

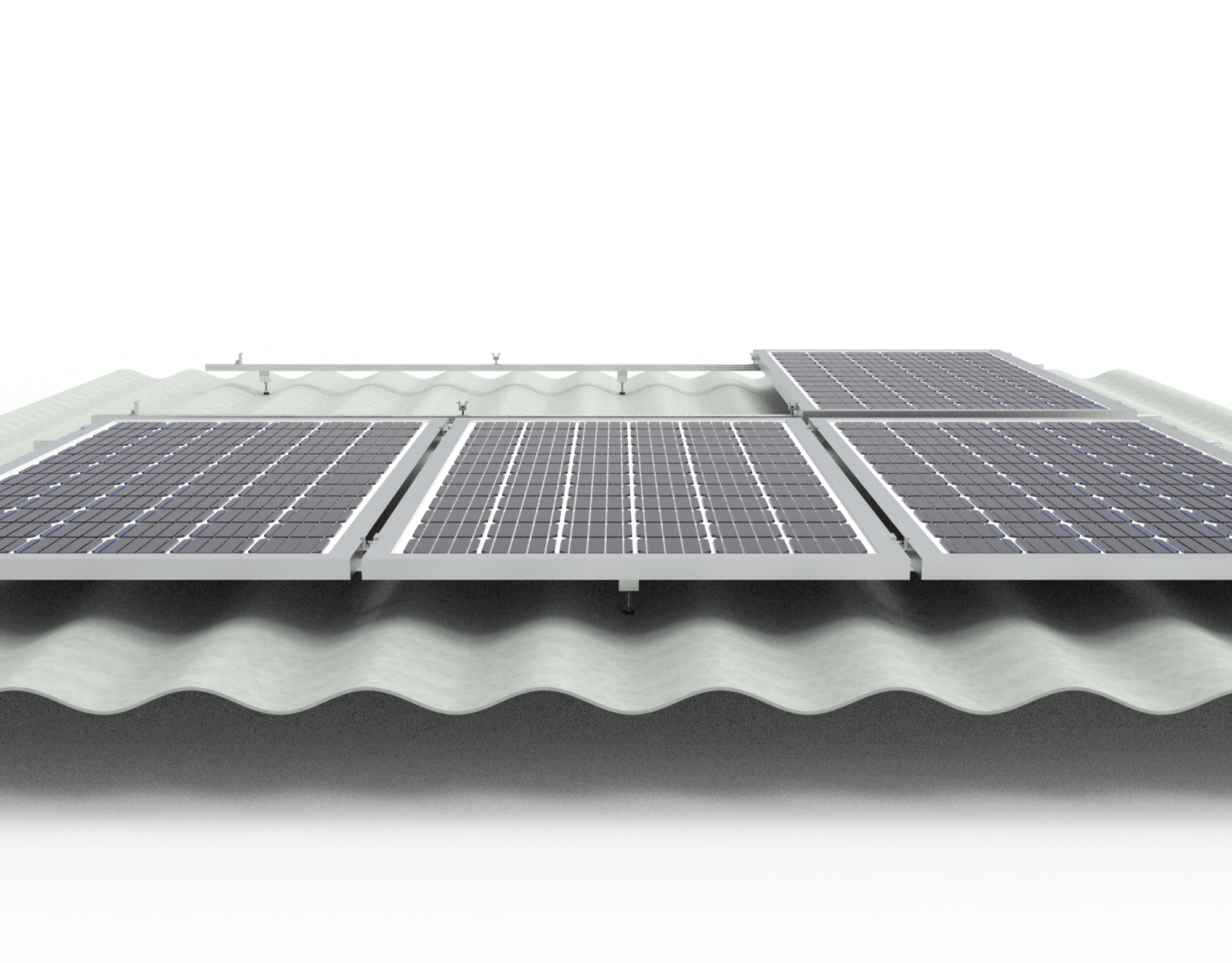

VIII. Fastener Chemicals for Extra Strength

Fastener chemicals provide additional strength and stability for roof-mounted solar installations.

These adhesives are used with bolts and screws to securely bond the mounting structure to the roof surface.

The typical application process involves:

- Drilling a hole in the roof material.

- Injecting the chemical into the hole.

- Inserting a bolt and allowing the adhesive to set fully.

Benefits of using fastener chemicals:

- Create an exceptionally strong and waterproof bond.

- Allow secure attachment to tile, metal and other roof types.

- Compensate for weaker roof materials.

- Resist weathering and deterioration over time.

Proper structural strength enables the solar system to:

- Withstand extreme winds, rain and other weather events.

- Avoid leaks, cracks and damage to the roof.

- Maintain optimal mounting integrity for decades.

Proper installation by trained professionals ensures maximum structural reinforcement and lifespan for your roof-mounted solar system.